Albion Timber – high quality British hardwood specialists

Owner and Founder of Albion Timber, David Smyth, is undeniably passionate about British timber, which is reflected in the company’s extensive stock and general ethos; this involves building up different varieties over a number of years and imparting much care and attention, which ultimately results in a very high quality product.

Having met David and the team at the recent North of England Woodworking & Power Tool Show in Harrogate, despite the fact the business has only been officially trading for a few short years, David’s story is certainly unique and one that deserves to be celebrated.

For those unfamiliar with this relatively new company, Albion Timber – a specialist hardwood timber merchant based in Sheffield – prides itself on the fact that all British timber is responsibly sourced from local forests and estates with good management practices in place, and imported and exotic timber from reputable, accredited suppliers.

Having stopped by Albion Timber’s stand during the ‘Harrogate’ show, I was pleasantly surprised to discover that David – along with the other employees – are so young, and certainly looked very dapper in their tweed suits. From meeting David, he’s clearly a gifted businessman who knows a great deal about the industry, along with having first-hand experience.

Formative beginnings

So where does this story start and how did David come to set up the business at such an early age? According to David, Albion Timber’s origins go back to when he was a young lad, embarking on the recently discovered hobby of woodturning. “I’d been to a local history group meeting with my father, where guest speakers – the Sheffield Woodturning Club – were discussing the history of turning.”

Continuing, David explains that this began a connection with members, which soon led to the purchase of the late club president’s old lathe. “At the time, I was too young to join as a member, but they were very kind and let me attend the monthly demonstrations. When the time came, I joined as a junior member and over the years, was given countless hours of help from many people there, and I’m eternally grateful for their support in aiding my development.”

With an obvious passion and affiliation for this wonderful raw material, which he’d been introduced to via his father and the new-found hobby of woodturning, it wasn’t long before the salesman in David was looking to make use of this skill, and soon joined the craft fairs and events circuit, selling his wares: “As time went on and my skills were honed, I also ended up selling work in various shops and galleries as well as taking on various commissions,” he tells us.

Given the fact he grew up on a farm, David therefore had access to felled trees and round timber via various friends and neighbours. Through the club, he then met Steve Wright of Elston Sawmill, who visited every other demonstration with blanks and timber for sale. “I started sending timber to Steve, who’d first mill it, then return it to me when he was next in the area.”

These proved to be formative beginnings, which sparked David’s involvement and fascination with sawmilling and the processing of timber into boards. “Steve was very kind and patient, teaching me a great deal about timber and milling,” he adds.

Quick growth

Having built up a name for himself in the industry and looking to develop his commercial interests – while continuing to work with this most-loved material – through a chance encounter at a future careers event, David’s path crossed with various members of the Wooldale Woodcarvers club. Making this connection resulted in David selling timber to other hobbyists, and he’d bring a selection along to the club’s Saturday meetings. “I wasn’t old enough to drive at this point,” he explains, “so was dutifully ferried there and back by my very patient mother.” However, it wasn’t long before David had a newly-acquired driving licence and vehicle under his belt, and was off up and down the country selling woodturning blanks to every club that welcomed him through its doors.

Wishing to set up an initial base for the business, David then requisitioned a stable on the family farm and opened a shop trading as Smyth Timber Supplies. However, he soon outgrew these premises and requiring more space, approached a neighbour whose arable farm no longer required the buildings and yard. “The space was much needed as I’d recently acquired a mobile sawmill and several lorry loads of oak logs. These were initially dried in the timber shed, but before long, the yard space was also being used to dry timber. Around this time, the trading name of Albion Timber was adopted, suggested by a friend who David had previously undertaken some work for.

With operations now in full swing, David’s next business move involved him selling the sawmill to release funds and using these elsewhere, and so began a long process of acquiring an increasing the amount of stock to accommodate the ever varied needs of a burgeoning customer base.

In order to cope with the growing workload, employees were soon required and with all hands on deck, a machine shop – which, according to David, is always humming with activity – was established for sizing and planing boards, as well as creating finished worktops and tables.

Machine shop

Owing to the fact it operates a full complement of machines, Albion Timber is therefore able to undertake a complete range of unique and bespoke jobs for customers, providing custom milling and machining. Drawing on extensive timber machining experience, such past jobs include those for structural engineers, architects, interior designers and a host of other industries. As David says: “While we typically produce standard runs of planed all round, tongue & groove, etc. we’ve ensured that our machinery setup allows for complex and individual tasks, not just big run-of-the-mill jobs.”

As with sawmill offerings, in addition to trade customers, the team has also helped many people who don’t have the capabilities for machining the timber they’ve purchased. As before, a full service is offered, which includes cross-cutting, ripping, planing, and even extends to sanding and finishing. For simple cutting/planing tasks, purchased timber is often machined ‘while-you-wait’.

Offering a broad range of services, Albion Timber also tackles a variety of unusual jobsin addition to more artistic work, including decorative wall hangings, art installations, and use of other media such as stone, metal and resin. As David explains, they also work alongside other craftsmen, taking care of the whole process and project. “We always welcome new and interesting jobs, whether commercial or private.”

The yard

Welcoming both trade and public to the yard, visitors are encouraged to drop by and browse through the racks of planed timber, which are all priced up. “We carry both kiln- and air-dried varieties, in as many species as we can get our hands on,” says David, and for any customers unsure of their exact requirements, the team of knowledgeable staff are always on hand to assist.

If you’re looking to purchase something specific, however, David explains that it’s always advisable to call ahead before visiting: “We carry large stocks in a warehouse that’s local to our yard, so if we know specific requirements, we can source this in advance and ensure we have the right timber at the yard when a customer stops by.”

Being a fully functioning timber yard, the outside space is also optimised to full capacity with stacks of drying stock, along with the machine shop. Carefully curating this over a long period of time, David is pleased to be able to cater for a wide range of customers looking to source wood, including that suitable for furniture making, joinery work, coach builders, musical instrument makers, architects, interior designers, structural engineers, home renovators, hobbyists – indeed, anyone who wants wood!

Sawmill

In terms of sourcing timber, David buys felled logs, usually straight from the forest floor, and their first port of call is the sawmill. Typically, these wait around until the schedule allows time for them to be cut, but in the case of more delicate species, such as sycamore, these are machined straight away, which ensures the best possible colour is kept.

“In addition to milling logs, there’s always cladding and beaming jobs that keep us busy,” and on this side of things, they provide oak, larch, Douglas fir and other timbers for jobs that require fresh-sawn timber. “We also cut logs, usually for our furniture making customers, who like to have full control over the drying process,” he adds. However, they’ve also milled timber for many customers who simply want to have furniture made from a particular tree – for example, one that holds particular sentimental value to them. “In these cases, we usually stick and dry the timber on their behalf, and in some cases, make pieces of bespoke furniture from it.”

Bespoke furniture

What really sets Albion Timber apart from other timber merchants, however, is the fact they design, build and sell a range of ready-made pieces of bespoke furniture as well as working to commission. Drawing upon a host of woodworking skills, offering this bespoke furniture making service also provides the opportunity to utilise the best hardwoods available. “Nearly all our furniture is made using timber we’ve seen through all stages of the process, from felled tree to finished board, and hand-crafted by us.”

Nothing is mass manufactured, there’s no automated processes, and no corners are cut. In addition, a dedicated upstairs showroom displays the furniture, flooring and oak doors, in addition to all hardware and fittings to match.

Upcoming open day

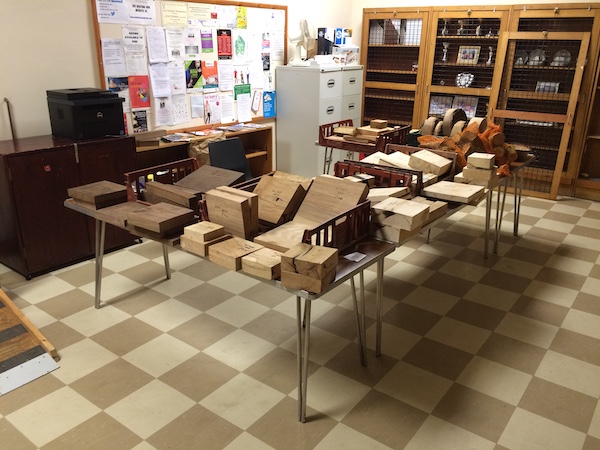

This brings Albion Timber’s story up to present day, but in addition to having built all of the above, the business now also boasts a fully equipped downstairs shop. Here, you can find a huge range of priced up planed boards, a dedicated woodturning and carving section as well as various abrasives, finishes, epoxy resin and much more.

Unsurprisingly, despite the fact he’s grown the business from nothing in such a short space of time, David is eager to add that this is just the beginning. “There’s lots planned for the future,” he confirms, starting with our first ever open day, which is due to take place on Saturday 18 May. We hope to see you there!”

A BROAD RANGE OF SERVICES

Albion Timber always welcomes new and interesting jobs, whether these are commercial or private.

Bespoke Furniture – choose from ready-made pieces, or commission a bespoke item. Nearly all furniture is made using timber David and the team has seen through all stages of the process, from felled tree to finished board, and hand-crafted by them.

The Sawmill – in addition to milling logs and cutting them for customers, cladding and beaming jobs keep the mill busy.

The Machine Shop – Albion Timber operates a full complement of machines and is able to complete unique and bespoke jobs for both trade and private customers.

FURTHER INFORMATION

Address: Albion Timber Ltd, Upper Hirst Farm, Hirst Common Lane, Birley Carr, Sheffield, South Yorkshire S6 1EX

Tel: 07580 627 921

Web: www.albiontimber.co.uk

Albion Timber will hold its first ever open day on Saturday 18 May – see the website for further details

- Log in or register to post comments