For the love of woodworking: a lifelong legacy – Jim Stickings FIOC: 1939–2023

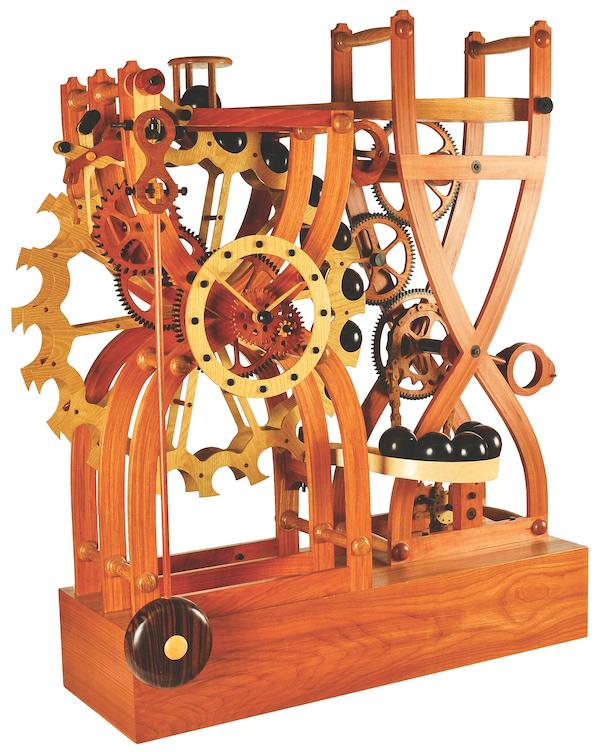

CLOCK COMPONENTS

• Constructed entirely from wood with a different species used for each of its parts – essential from an aesthetic and wear point of view

• African blackwood arbors fitted into lignum vitae bushes

• Frame: 5mm-thick laminated English cherry

• Wheels: three pieces of English cherry laminated to form plywood, with African blackwood teeth and boxwood pinions

• Escapement frame: 0.7mm-thick veneers to form a walnut plywood with African blackwood counterbalance weights

• Spring composers & pellet arms: formed from walnut and ash veneers respectively

• Escapement balanced by adjustable African blackwood counterweights

• Pendulum bob: rosewood with a limewood insert to hide the regulator nut

• The pendulum is suspended on a knife edge support of African blackwood with beat adjusters in the same material

• Paddle wheel: ash veneers with Afzelia spacers, and African blackwood balls used as the driving force

• Ball lift wheels & pinion: made using identical materials to the clock

• Frame: laminated pear wood; drive chain: walnut veneers and lignum vitae spacers with a walnut veneered clip. No glue was used in the chain’s construction; just a tight fit with the links and spacers

• Ball catchers: Afzelia; top ramp: 1.5mm birch plywood; base: English cherry, driven by an electrical motor housed within

If ever there was a lifelong reader we’d be privileged to feature, it’s Jim Stickings, who sadly passed away on 6 January 2023, aged 83. An avid reader and collector of this very magazine, he amassed 697 editions in total, dating back to the 1930s. This feature serves more as a tribute to Jim and his incredible body of work, not to mention the fascinating story of his journey to discovering woodworking and the final pièce de résistance – the mesmerising all-wood timepiece pictured above.

Simply put, Jim Stickings was a technical wizard and an extraordinary talent, who’s passion for woodworking knew no bounds. This was made all of the more profound owing to his desire and eagerness to share such knowledge and skills with other woodworkers, which he always did with overwhelming enthusiasm.

By means of an example, a talk he gave to Kent Woodworkers on the making of his all-wood clock included a PowerPoint presentation comprising over 150 slides, which goes some way to demonstrate the minute level of detail Jim had included.

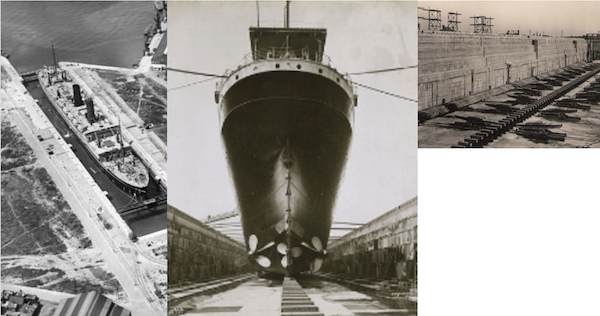

Apprentice shipwright

Hearing and reading about Jim’s life story, from early beginnings to his quest to design and make a clock entirely from wood, not to mention the extra projects he somehow found the time to undertake, one can’t help but wonder where it all began. In order to find out, we have to go back to 1939 and the port town of Tilbury, in Thurrock, Essex.

Jim left school aged just 15 and from here his woodworking career began, as an apprentice shipwright – another name for a ship’s carpenter – at Green and Silley Weir, Tilbury Docks. This role allowed him to gain experience in maintaining and repairing ships, mostly working on wooden parts such as the external hull, once in dry dock. This was a time when P&O had cruise ships such as the SS Himalaya, which operated a regular route from here to Australia.

Ted Izod – an inspirational mentor

Part of Jim’s apprenticeship required him to attend college so that he could learn the necessary skills. During this time, he’d go on to meet the person who’d prove instrumental in his future career – which would span some 35 years – lecturer, Ted Izod.

Described by Jim as his “inspirational mentor,” Ted immediately recognised the raw talent and nurtured his creativity, which resulted in Jim going on to successfully complete his City & Guilds Intermediate, Final and Full Tech exams. Back then, this involved a four-hour theory test followed by a seven-hour practical, with the students having no prior knowledge as to what they were required to make.

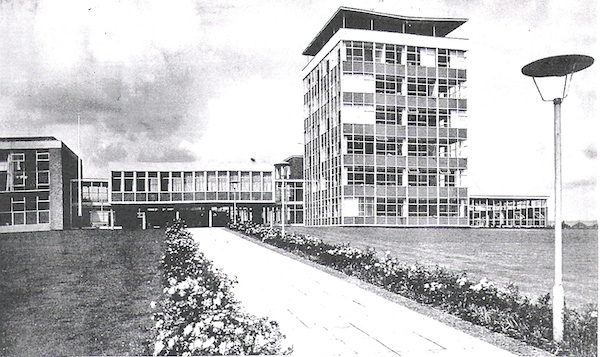

Thurrock Technical College

On completion of his apprenticeship, Jim began working for a firm of specialist shopfitters in London, with a high-end client list consisting of Salvatore Ferragamo and Mary Quant, all of whom he completed projects for.

Clearly making waves in the industry and with positive praise being exchanged, it was during this time that Jim found himself being approached by staff at Thurrock Technical College, who asked whether he’d be interested in teaching woodwork to an evening class of would-be DIYers. He agreed and owing to the high praise received by the College, Jim was duly offered the position of Lecturer in Carpentry and Joinery, which he happily accepted.

Giving up his job in London, Jim now had the opportunity to share and pass on his impressive skillset and immerse himself in full-time teaching at the college. Here, he was also reunited with old mentor Ted Izod, and the pair ended up working together for a number of years.

Senior Lecturer in Carpentry & Joinery

Such notable points in Jim’s career include his involvement in the College’s opening ceremony, which was attended by Prince Phillip, Duke of Edinburgh. When Ted left to go and work in South Africa, Jim was subsequently promoted to Senior Lecturer and Head of Department.

In this role, Jim loved teaching young apprentices the necessary skills required for their chosen trade, such as how to cut a roof, make a staircase or sash window, as well as correct use of woodworking machinery in preparation to taking their City & Guilds exams. Such was Jim’s level of expertise that as well as day-to-day teaching, he also coached mature students in such skills as musical instrument making and marquetry.

The Institute of Carpenters

In recognition of his services to woodworking and incredible depth of knowledge, in 1994, the Carpenters’ Craft Competition Secretary wrote to Jim at Thurrock Technical College, explaining that the competition contained an award for the College’s woodworking department, which trained the successful candidate in the College Awards Section, and that this year, the honour was given to Thurrock College. As such, Jim was invited to Carpenters’ Hall in London, to attend the presentation of selected awards as well as receiving £200 for use within his own department.

The Carpenters’ Craft Competition – sponsored by both the Worshipful Company of Carpenters and Institute of Carpenters – is the only national one of its kind open to students of carpentry, joinery and shopfitting, and over 200 colleges nationwide are eligible to take part. It gives outstanding students the chance to showcase their work and have it judged by leaders in the field, as well as aiming to encourage and reward highly motivated students who’re prepared to go that extra mile in order to achieve the highest possible standards.

The following year, Jim went on to join the Institute of Carpenters, very soon becoming an active member of the Central Section Committee, and most recently, was awarded Life Membership of the Institute.

House building projects

While working in London full-time, Jim embarked on the first of many building projects, starting with the demolition of a property that had been affected by the 1953 floods, and going on to construct a three-bedroom bungalow for him and his wife. After a few years and now working solely at Thurrock Technical College, Jim took the opportunity to complete another new-build. He acquired a site with very poor ground conditions and difficult level variations, which many had already disregarded, but unlike them, Jim saw the potential and relished the challenge.

Given his can-do mentality and problem-solving attitude, Jim overcame these obstacles and went on to build a three-storey house for his young family, completing all the carpentry and joinery himself, from cutting the roof, to making the staircase, not to mention constructing all the windows, doors, kitchen units and wardrobes.

As ever, Jim was always motivated to go above and beyond, pushing himself further still, and in doing so, took on the ultimate challenge posed by another new-build, which involved demolishing a house that’d been unloved for many years. Clearing an overgrown site, he proceeded to construct a very large and extremely stylish house, again using all relevant skills to complete it single-handedly.

The company that supplied the handmade roof tiles was so impressed with the completed house that they chose to feature it in their sales brochure. Not long after this, Jim retired from Thurrock Technical College and started the next chapter of his woodworking career – making various clocks entirely from wood.

Preparation is everything

Regardless of the project he was undertaking, Jim always reverted back to the lessons taught during his apprenticeship years that ‘preparation is everything’ and the importance of ‘building it in the mind before you get to the bench’. This disciplined approach and mindset followed Jim throughout his career and these teachings served as a mantra that he carried with him, which influenced all aspects of his life.

Even when diagnosed with terminal cancer at the beginning of January 2022, and reluctantly having to call time on his beloved hobby, Jim went about calmly and methodically disposing of his tools and machinery. Even then, he still had the creative need to work with wood, so began building a model boat. Sadly, however, he wasn’t able to complete it, and this is the only project that remains unfinished.

Wooden clocks

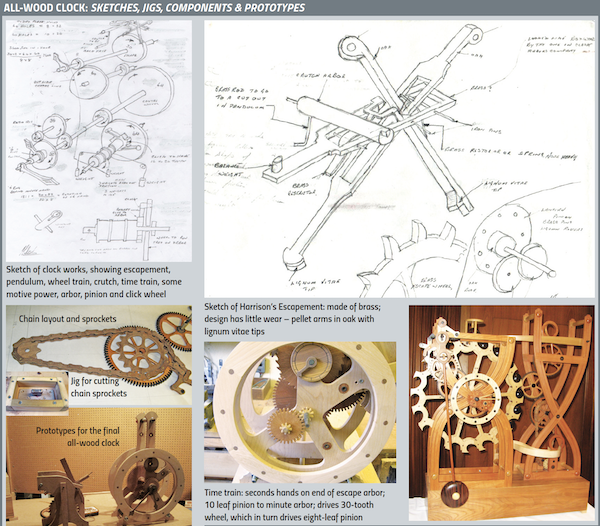

With woodworking being Jim’s greatest interest since childhood and having retired from teaching, he began to further explore clockmaking, with his initial interest in the subject being sparked as a result of seeing some ornate wooden long case clocks. Discovering this interest was in fact shared with an engineering colleague at the college, the pair went on to construct two long case clocks, combining their respective skills: the two movements were made by the engineer and Jim provided the woodworking element for both cases.

Jim’s interest was further piqued after seeing some clocks with very few moving parts, which led him to wonder whether he could construct a timepiece entirely from wood. Carrying out further research into how clocks work, Jim came across John Harrison and his famous grasshopper escapement. The next step was finding out how to calculate this value, and in doing so, he came across an article written by Kenneth James in the Horological Journal of January 1985. Using this new-found knowledge, Jim was able to calculate the dimensions required and set about making a prototype, which much to his surprise, actually worked.

From this point, Jim’s clockmaking journey began in earnest, and he soon completed his first project, which was driven by a lead weight. But in typical Jim fashion, he wanted to go a step further, so returned to his original idea of creating an all-wood timepiece, and began experimenting.

Research now focused on some alternative motor power and during an exhibition he attended, Jim came across a clock that used a paddle wheel, designed by Nicholas Radeloff (1650). Using this idea, he succeeded in constructing the clock from timber alone, which took him the best part of 2-3 years. Jim wasn’t fully satisfied, however, as the balls had to be manually lifted to the top of the piece in order for the cycle to start again.

In 2009, Jim delivered a presentation to the Institute of Carpenters, at Carpenters’ Hall, and soon after, began researching a means of raising the balls up to the top without having to rely on manual intervention. While attending a model engineering exhibition, he spotted a glass marble lift, used as part of a display, and worked out how to adapt this idea for the ball lift. Doing so involved a further two years of work, which finalised the clock’s development.

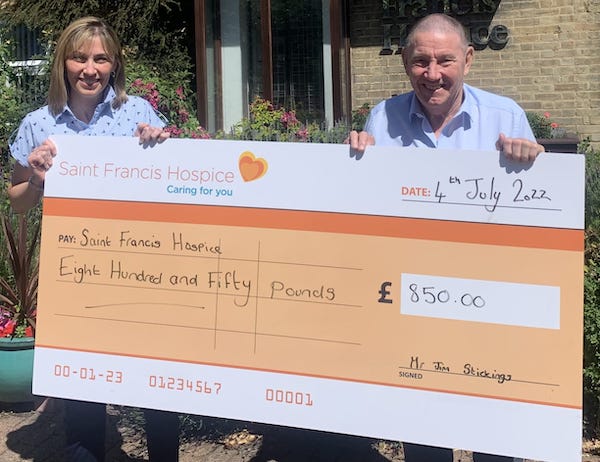

With the clock completed, Jim gave a series of presentations detailing the steps for designing and making his all-wood clock, with the aim of raising money for Saint Francis Hospice, who’d previously cared for his wife. Talks were received by The Institute of Carpenters – London and Kent sections – as well as the Kent Woodworkers, Fine woodworking students at the Building Crafts College in Stratford, London, followed by Kent and East Anglia sections of the British Horological Institute.

Jim subsequently made two more wooden clocks, completely different in design to the first, but using the same method for telling the time. The first of these proved to be Jim’s greatest achievement, and looking at this piece – pictured at the very top of the page – it’s clear to see why. The table of clock components lists each individual part, and goes some way to demonstrate the magnitude of technical detail Jim had included, even though most of us will never be able to comprehend just what this involved.

Clock auction

Once Jim had been diagnosed with terminal cancer, he made the decision to sell the clock, wishing for any monies raised to be donated to Saint Francis Hospice. With the help of his daughter, Joanne, details of the clock were sent to Sotheby’s in London. Shortly after and in awe, their clock specialist made contact, commenting on the fine craftsmanship and skill involved in its making.

With his guidance and recommendation, an auction house specialising in the sale of unique clocks took on the project, and in May 2022, the piece was sold at auction, raising £850, which was donated, as per Jim’s wishes.

While this article only manages to encapsulate a small amount of the wonderful work Jim undertook throughout his life, it’s heartening to know that his influence lives on, not only in the pieces he created, which will forever be cherished by their owners, but also in the teachings passed on over many years. It’s true to say that Jim has certainly left an indelible mark and lasting imprint on the lives of so many people throughout the course of his long career.

Remarkably, Jim’s love of woodwork and creative impulse continued to grow throughout his life, staying with him till the end. Importantly, he was able to share this passion and inspire others, going on to complete the most technical of projects, and will forever be remembered as someone who contributed so much to so many.

Praise for Jim

Institute of Carpenters – Eulogy by Retired Chairman, Central Section Committee

“One day Jim suddenly said, out of the blue, ‘I’m going to design and build a wooden clock’ – and what a comment that turned out to be! Jim was a perfectionist in all he did and a solver of problems when needing to produce a number of amazing timepieces. To see his sketches and detailed drawings, and his quite unique way of producing some of the very intricate clock parts, you can only marvel at the amount of time he must have spent in solving any problem.

Jim was without doubt a modern day version of Carpenter John Harrison and his remarkable wooden timepieces to solve the problem of finding longitude when at sea, way back in the 1720s, when an accurate clock was needed. Jim’s attention to detail and accuracy was quite amazing! During any demonstration, and after setting up his clock, he’d often have it working alongside him as he delivered the talk.

A further example of Jim’s amazing abilities was way back in 2014, when he introduced Central section members to ‘Getting Started with TurboCAD’. He’d used this method when producing drawings for his clocks. As Jim said: ‘Its really just like using drawing instruments, which we’re all used to, but on a computer!’

His aim was, in 20 minutes, to go through the ‘easy stages’ to obtain the lengths and bevels for a hip rafter roof of unequal pitches, no less. He even produced a 31-page booklet to guide us through. The work that this alone involved must have been considerable and yet another example of his technical brilliance for detail.

Jim was a long-standing member of the Institute of Carpenters, and his activities and contributions, especially in the Central Section, will be greatly missed. One of his activities as convener of the Central Section Visits Committee enabled members to enjoy many excellent social networking occasions, which were very well supported.

Another string to his bow was giving outstanding lectures and probably the most remembered were those relating to the fantastic ‘all-wood clocks’, which he designed and made. Absolutely brilliant.”

Thurrock Technical College – fellow lecturer

“I started attending Thurrock Tech in the early ‘70s as a joinery apprentice, which was when I met and went on to be taught by Jim Stickings – a wonderful lecturer who was able to put across the most complex of construction tasks to his students in a manner we all understood.

Jim had worked his way up through the tools and had an empathy towards the students, which allowed him to draw the best from them. If you ever asked Jim something he was unsure of – normally higher maths – he’d say so and tell you he’d find out for you. He always did but in addition to that, would also go on to successfully explain the problem.

I remember learning the wonders of trigonometry from Jim and applying it to roof construction. We didn’t have calculators, so instead used four figure tables or slide rules. Jim offered me the job of Technician at the college, which I did for a couple of years before being offered the opportunity to also teach some evening classes. Very soon after that a lecturer’s position became available, which Jim put me forward for.

During my time at the college, I witnessed many of Jim’s construction projects taking shape, all of which featured his college-made joinery. I had the opportunity to see and help out with many of these, and one of particular interest was the production of tilt and turn windows. These were incredibly complex and required very accurate machining. I still make similar windows today, inspired by him.

He also taught musical instrument making in the evenings, which was very much a social club and ran for many years. A lot of specialist equipment was made in college for the instrument makers and exotic materials sourced accordingly.

I recall the panic once while in the timber store and looking at the music-only rack, where piles of dust had appeared under one of the slabs of fruitwood – wood-boring beetles had emerged! The material was cut open to reveal live grubs, which had to be sent off to a lab so the species could be identified. A sense of great relief was felt when we learnt that these beetles only attacked one particular timber type, and luckily this was the last of it.

Jim also taught Essex Teachers the safe use of woodworking machines, which led to yet another social evening class where participants would make all manner of things in the workshop. These presented a pleasant change to the more demanding certificate classes.

Another of Jim’s projects while at the college was making long case clocks, using movements that were handmade by one of the engineering lecturers. He was also involved in making gear cutting engines, which allowed him to build further timepieces. As a result, I became interested in AutoCAD and produced drawings for an identical clock case, which I later made using a German movement.

Many of our students went on to start their own businesses, and often sent apprentices for us to train; we always felt a particular sense of achievement when this happened.”

- Log in or register to post comments