Repeat Edge sharpening system from Shenton Woodcraft

Nigel Shenton first started his working life as an apprentice patternmaker, in both wood and metal. Despite moving into the design and development of high volume metal products, Nigel has always remained a keen woodworker.

Over the last few years and through developing his turning skills, Nigel found that he was becoming become increasingly more frustrated when it came to sharpening turning chisels. As any woodturner knows, the range of tool sizes and shapes available is many, so constant adjustment of sharpening equipment and techniques is necessary when using such tools. Many turners don’t like sharpening due to this complication and this task will often be put off until absolutely necessary.

Nigel looked at almost every system on the market and found the majority required much effort to set up, but more importantly, re-setting up to repeat the grind or edge exactly as it was before.

As a result of this frustration, Nigel decided to design his own, drawing on previous experience, which came in very handy, and it wasn't long before he had prototypes made and ready for testing.

Nigel discovered that the more he used his new system, the more he realised just how much easier it was to keep changing tools and touching them up. Believing that if he thought it worked well and saved time, then others would too. According to Nigel, it almost makes sharpening a pleasure!

Following a period of testing and design tweaking, the final design was finalised, a patent applied for, a manufacturer found, and stock delivered.

The Repeat Edge sharpening system uses a very simple design and the main difference to others available is that once you've set the perfect grind/angle, a piece of scrap wood is then cut and dropped into the jig to set that position.

The piece of wood can be then marked to reflect the tool - for example '25mm spindle roughing gouge', so it can be easily identified later. One customer has even colour-coded his chisels and scrap wood.

This makes returning to the grinding wheel so easy: simply select the piece of scrap wood assigned to that particular tool, drop it into the jig, push the jig in until it stops on the scrap wood, tighten the jig, start the machine, and begin sharpening.

The tool goes into exactly the same place as before so just a couple of light touches are all that's required on the wheel to restore the edge. There's no heat build up and very little wear on the wheel or tool, so tool life is therefore prolonged and the operation very quick.

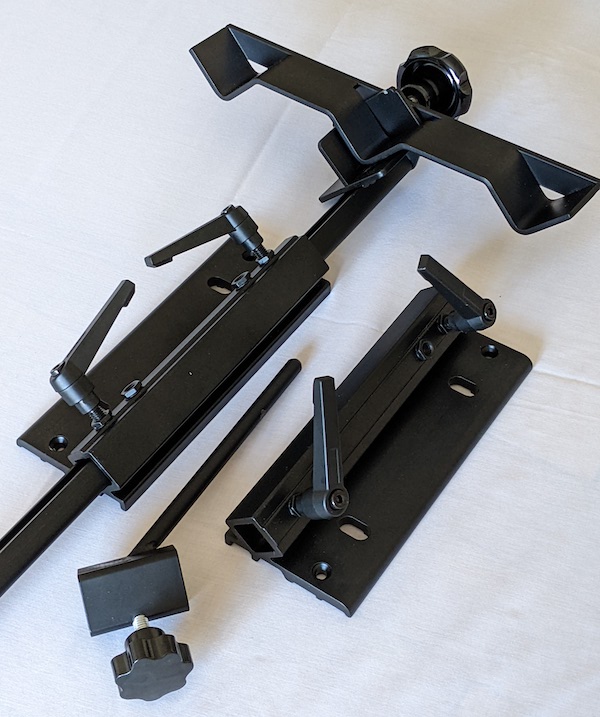

Included in the kit:

* Two baseplates – one for each wheel of a double-ended bench grinder. The jig will work with most 150mm and 200mm grinding machines.

* A main arm that'll do most bowl gouges, spindle gouges, spindle roughing and parting tools.

* A skew attachment that secures to the end of the arm and allows you to sharpen skew chisels.

* A side grind or fingernail attachment that's located in the socket of the adjusting arm and rocked from side to side to produce the side grind in the usual way.

* The position of these attachments can be set with pieces of scrap wood, so the position can be set in exactly the same way.

Priced at £115 – plus delivery – see www.shentonwoodcraft.co.uk for further information.

- Log in or register to post comments