A starter toolkit...

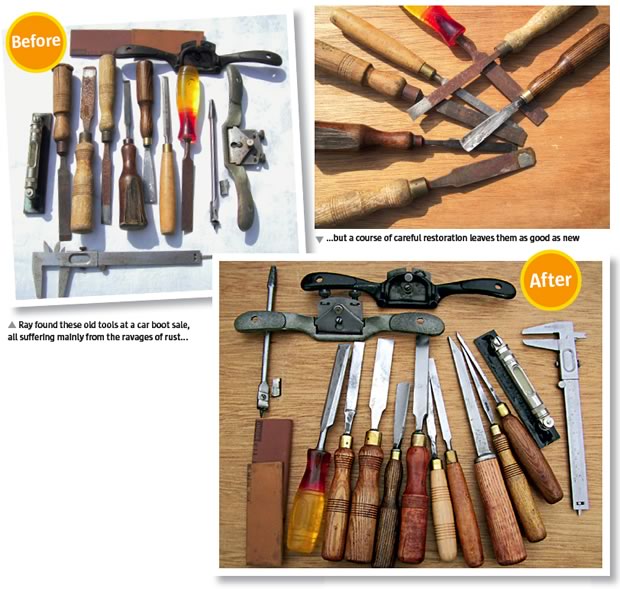

Keeping your workshop supplied with machinery, timber and finishes, as well as doughnuts and tea, is not cheap. It doesnt help the wallet one bit, either, when you have a penchant for quality hand tools. Theres no need to despair, however. As I explained in GW202:27 when I discussed vintage planes, I find car boot sales are ideal for tracking down old, rather tatty tools that can be renovated. This time were on the lookout for wooden-handled chisels, spokeshaves with cast steel blades and a few other items to get your collection started.

The steel in old tools can be of better quality than in some modern counterparts, although the tools will need a bit of attention. For a start, theyll need a good clean and de-rust, the handle will probably have to be tidied up, and the blade sharpened and honed. After this, however, they can provide years of service, if treated well. Its my belief that a lot of tools suffer more from rust, poor storage and bad sharpening than they do from hard usage. A chisel with a badly split handle will look as though its had a hard life, but more often than not, its blade will be fine and will renovate with a replacement handle into a useful tool.

This thinking can apply to a wide range of salvageable tools and, although the worked-on tool will not have the same cash value as a new one, it can often do the same job. Whats more, youll have learned a bit about tool restoration along the way.

Hunting for goodsRecent trips to car boot sales have landed me a collection of six assorted chisels, two shaped slipstones used to hone gouges, and a very old spokeshave with an adjustable mouth, possibly made by Preston; perhaps eighty or more years old, this kind of shave is considered to be better than the more common types. Ive also found an engineers spirit level, useful for setting up machines, benches, frameworks and the like, and an adjustable wood-boring bit with two cutters, used with a hand brace to make any size hole in its range. All of these were pretty cheap and if you look at good modern chisels to compare prices, youll see the kind of bargain that can be had.

As with damaged handles, dont let a blemished blade put you off. Ive found many tatty tools that still show the makers original grinding marks, and so a bit of a clean and sharpen should put it back in the kit.

There are other things to consider when making a prospective purchase. At the price and with a bit of work, would it still be a bargain? Hold it by the handle and look along it to see if its bent or distorted, bearing in mind deliberately designed bends or curves. If the handle is bent to one side, it could be a bent neck or a bent tang or a badly fitted handle. If the handle is loose, pull it off and if the tang looks okay, you can re-fit the handle with a bit of slow Araldite and/or a sliver of wood.

I suggest you try to find a fairly good tool or two to begin with, then progress to scruffier items as your skills increase. It would be good to get hold of a metal spokeshave there are various styles such as flat face, round face and adjustable mouth, as well as the fairly modern style with two adjuster knobs. They need a decent length blade and a front plate to hold it in; a spare blade can be obtained for about £4 or £5. You should also keep an eye out for bench chisels, again in various styles such as bevel edge and mortise, as well as gouges and carving tools depending on your working practices. If you tap two good chisels together they give a ringing sound, while poor quality ones sound more flat and dead. Other items to think about are draw knives, marking knives, cutting knives, bradawls, sharpening stones, marking gauges, spirit levels, hammers, pincers, pliers and mallets.

I have an electric motor mounted on a block of wood that can then be held in a vice, and a small drill chuck fixed on the end of the spindle in which I put various grinding bobs, sanding drums, flap wheels and small shaft-mounted grinding wheels. I use these to regrind and polish up the inner canal of a blade, which needs to be very clean and smooth where it meets the bevel, and at least a bit more to allow for further sharpening. The other side can be cleaned up on a rubber disc-type wheel with an emery disc on it held in the motor. Work with the wheels rotating away from you, wear eye protection and a dust mask, keep fingers away from even blunt edges and keep a handle on to protect hands from the tang, which is sharp enough to go deeply into your hand if it gets caught when grinding or polishing.

Youll need a selection of emery cloths, as well as wire brushes, sandpapers for wood, a few drill bits, rust killer, paraffin, white spirit, meths, stain, button polish and plenty of rags.

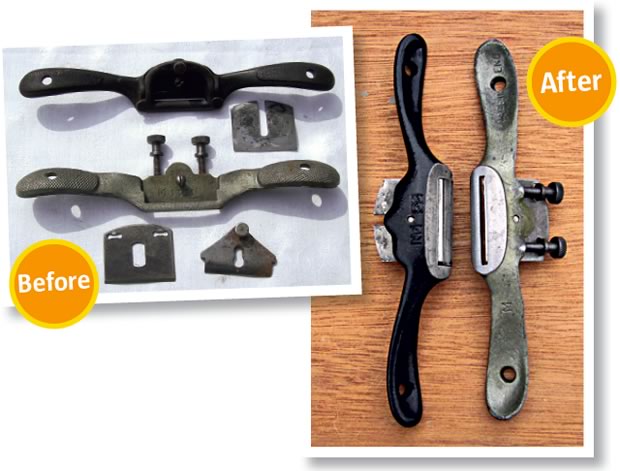

Remove all screws and knobs, and leave them to soak in a drop of paraffin in a tin can these parts are often non-standard so dont lose them. Old paint can be removed with paint stripper as per instructions and wearing gloves and goggles, then cleaned up and neutralised with white spirit, wire-brushed, emeried and any residual rust killed off with Jenolite rust killer. Dont overwork the mouth area and working face, just follow the shape with a strip of emery held along a flat file. A good wire brush is needed to remove any loose killed rust, then apply a thin coat of primer followed at intervals with two coats of enamel the same as the original colour.

Having cleaned up all the screws, knobs and blade, assemble the tool and try it. When refitting, do not force tight; if you think they may unscrew, put a spot of paint on the end before screwing. Start with the blade only just protruding, try a cut and adjust to suit. Most tools only want a common-sense approach to cleaning and painting, but sharpen them properly and youll end up with a decent tool.

A handle that has to be struck with a mallet needs to be sound, but for general hand use, itll be fine as long as its sanded down and stained with something like Georgian mahogany, followed by two or three coats of button polish, a gentle smooth with well-worn sandpaper and a final light polish with furniture wax. A slightly loose handle can be refitted with a sliver of wood and Araldite. Make sure that the handle sits in line with the blade before tapping fully home. Sight down the handle and blade and if its not in line, remove and rotate the handle through 90° and check it again.

There are normally four possible handle positions on a four-sided tang, but when you have the best position, put a little mark on the handle, such as a bit of masking tape, for lining up when you tap the handle (with a small amount of Araldite in it) onto the tang. Never drive a handle on with force. If its a new one, drill holes of different diameters to make an approximation of a taper that will tap on and off the tang to within about 5mm of the shoulder; a firm tap should seat the handle. You should now be ready to grind/hone the edge. Draw knives clean up like a wide chisel, but do be careful of long sharp edges.

Excellent hammers of various sizes and weights can usually be purchased for little cost and are easily cleaned up, plus a touch of paint just make sure that the handle is tight, and the head securely wedged onto it.

I think thats a good start to a hand tool collection, costing a fraction of the price compared to buying new. I feel that seeking out and renovating these items is a great hobby. For a start, it provides fresh air and exercise! But most importantly, you get loads of great tools out of it.

- Log in or register to post comments