Comic cuts

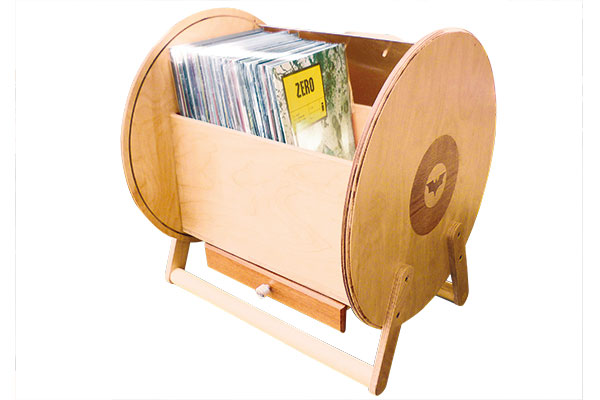

The design of this storage drum to house my growing collection of comic books is drawn primarily from Postmodernism, as the circular design isn’t necessarily practical or efficient, but is unusual for the sake of it. I felt that it would be more aesthetically pleasing than a cardboard box, which seems to be the only other available storage solution for comic books.

I also wanted the unit to subtly reflect the items that were being stored, so I added the iconic Batman symbol as an inlay onto one of the circular sides. During the design phase, I also took panels from comic books, and used shapes and images from them to incorporate into the design. The final design I settled on actually began as the ‘Owl Ship' from Watchmen.

Essential ingredients

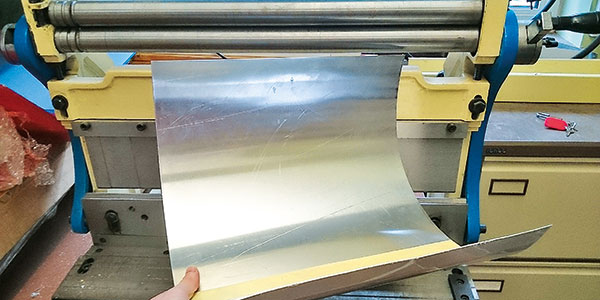

All of the comic books stored within the drum must be protected from light, to prevent them from fading, so I decided on a rotating aluminium cover that would allow easy access to the contents while also covering them. The drawer beneath allows tape for sealing comic bags to be stored. I chose plywood as the primary material to keep the unit lightweight but durable.

Machine precision

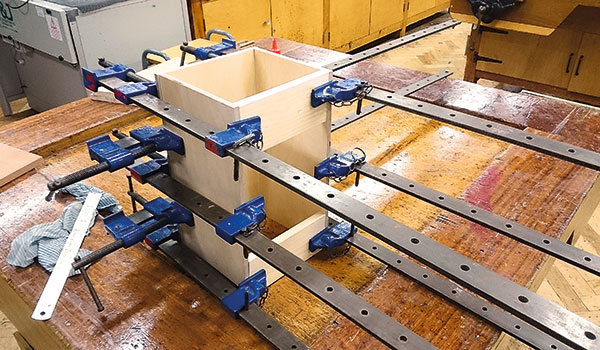

Some of the components, such as the circular sides and their grooves, were cut on a CNC router. I used a laser machine to cut the small Batman pieces for the inlay. All the other pieces of wood were cut by hand or using a bandsaw, and the aluminium sheet was bent to shape using a metal roller to form the lid. Pop rivets connected the handle to the lid, and simple comb joints were used for the drawer and main body. I also created a handle for the drawer on a metal lathe, and used a knurling tool to create a grip.

Final tweaks

The main difficulty was ensuring that the lid would fit in its grooves and open and close smoothly. Thankfully, I managed to achieve the perfect shape after lots of readjusting. I also added beeswax to the grooves and rail of the drawer, which would allow them to move more smoothly. I’m very lucky to have had all of the resources available to me in the design and technology department of Bootham School, as well as the technical expertise and support of my teacher, Eamonn Molloy.

- Log in or register to post comments