A guide to buying second hand kit

secondhand machinery will not suit all woodworkers, but if you are prepared to invest some time in finding your table saw, bandsaw, planer-thicknesser or spindle moulder then you may be able to find a bargain.

Anyone over the age of 40 will tell you ‘they don’t make them like they used to’, and this is very apparent with woodworking machinery. There’s certainly been a shift towards building to a price rather than building what’s best for the job.

Probably the main reason why used machines can be such good value is that it’s possible to pick up industrial machines for the same price as new ‘home woodworker’ models. Industrial machines are designed for longevity, accuracy and easy maintenance not for the marketing team on the first floor. They may have had a previous life in a school, prison or joiners, which also means they were probably quite well looked after, and I bet an old cast iron machine will be more accurate than a shiny new aluminium one after you have dropped a 3in plank of oak on it a few times.

The downside. Of course, is their large size and weight. They may also be less safe than the modern equipment that meets today’s rigorous health and safety standards. Whilst maintenance may be easier to perform, some parts may be difficult to source. Although parts tend to be standard and simple so replacements can be found or reproduced

Ask yourself if you really have the right workshop. Can your shed really take a half-ton planer with a one and a half metre table?

You also need to consider power. Most industrial kit requires a 3-phase (industrial 415V) power supply and whilst there are some rare examples of single-phase (domestic 240V) machines these are usually snapped up very quickly and are more expensive. You can run 3-phase machines from a domestic supply using a converter, but this adds cost (a 3hp converter will cost around £500), you loose the benefit of the power and machines run less smoothly.

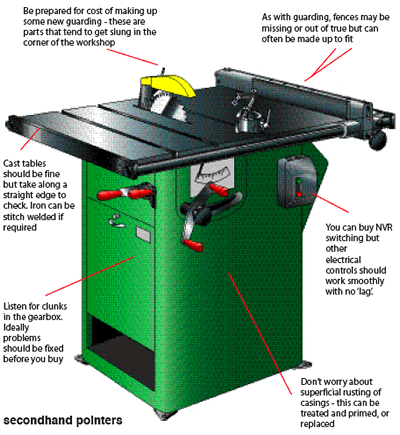

The basic rules apply to machines of all types - bandsaws to spindle moulders. They are all basically a motor, gears, bearings, castings and a bed (or table). Beds and castings - These are the most important components of your machine since everything else can be replaced. Check for cracks and breakages. It is possible to stitch-weld small cracks in cast iron and I have found local companies that are prepared to fabricate replacements, but this will add cost and hassle, there are plenty of good machines already out there with sound castings.

Use a straight edge to check the beds are flat. Heavily used machines may have worn or scored areas that could be re-ground but it may be easier to find another machine with a flat bed.

Do not be concerned about light rust or small dents. Provided the rust has not pitted it can be cleaned off with wire wool and oil. If dents are large enough to affect your work you can fill them using a cold repair kit.

Go to an auction as a spectator to see how it works but when you are buying you should register your interest in a sale, get a catalogue and check the terms and conditions. Look for the following points.

Hidden costs: There may be a buyer's premium (typically 10%) and VAT to add to the bid price.

Payment terms: An immediate deposit is usually required when the hammer falls with full payment by the end of the day. Cash or bankers draft may be the only acceptable form of payment.

Pick-up: The lot is yours when the final bid is accepted and the auctioneer may want your machines off his site the same day. Your bid will not include delivery.

Viewing: There may be an open inspection day before the sale otherwise you will only have a short time before the auction begins. Do not expect the opportunity to start or use the machinery but you should be able to handle it.

Guarantees: Lots are usually sold as seen with no guarantee. Some auctioneers may allow a few hours after the sale to find fatal faults.

Remember the golden rules:

1) Decide your price limit before the sale and stick to it.

2) Keep your eye on the lot numbers - bidding for the wrong lot could be costly!

Bearings and gears - Wherever possible you should try the machinery before you buy. Listen and feel for grinding, clonking or any other roughness, but don’t let it put you off. Even in very old machines, bearings are usually a standard size and are easily replaced.

If it feels like there is a drive problem the gears may be at fault. Replacing components in a drive speed gearbox will be more time consuming than a straight rise and fall, but both can be done. Take this into consideration when negotiating price and ask the seller to fix it as a condition of sale.

Guards, tools and accessories - Make sure that the machine has all the correct guards and essential accessories. The guards are essential to your health so if they are missing then walk away.

Accessories can go astray, a sliding mitre fence may be mislaid in a dusty workshop but they can be replaced or alternative solutions re-engineered. Take this into consideration when you negotiate the price, a missing spindle moulder ring fence may give you bargaining power and be cheaply replaced by your local engineering firm.

Blades and cutters are not usually supplied as standard but machines should include at least one set, even if rusty. If a machine comes with non-standard accessories take them into consideration when looking at the price - I bought a mortiser that looked expensive until I considered the set of six high quality chisel bits included, worth over £200.

Electrics - All buttons should be clear and work on the first press without sticking. Look for a no-volt release (NVR) switch, if it does not have one then get one fitted.

Consider the power ratings. Three-phase equipment needs to be hardwired to your supply so get an electrician to give you a quote. If you are running 3-phase equipment on a domestic supply courtesy of a converter then do your maths, I know several people who have attempted this and each one has had to upgrade to a larger converter.

Warranty and maintenance - If you buy from a retailer you should get a guarantee that the machine will be delivered in good working order. In some cases you can negotiate an additional warranty.

All of the retailers that I spoke to were prepared to arrange on-site maintenance with a call-out fee around £25 plus materials (cheaper than a plumber!). Remember that getting spares for obsolete machines can be a lottery but the retailers were confident that parts could be re-engineered if no spares were available.

EPS Ltd

01984 624273

www.eps-services.co.uk

Scott & Sargeant Woodworking Machinery Ltd

?01403 273000

www.machines4wood.com

Despite the volume of available used machinery they can still be quite difficult to find. Most retailers that advertise used machines tend to deal with larger factory models that are less suitable for hobby use and some do not like dealing directly with the general public. I found AE Coles (Bridgwater) Ltd and Scott and Sargeant Woodworking Machinery very helpful and they both publish stock lists on their websites (contact details in the box above).

Real bargain hunters may choose to bid for their secondhand machinery online at the auction site www.ebay.co.uk. But if you really want to feel the blood in your veins go to a liquidation auction (often advertised in the classifieds of your local rag). The downside of course is that you are buying as seen. If the machine does not start when you get it home, tough luck!

When you go to view a potential purchase remember not to be put off by its appearance, there may be a gem under all that dust and rust.

- Log in or register to post comments