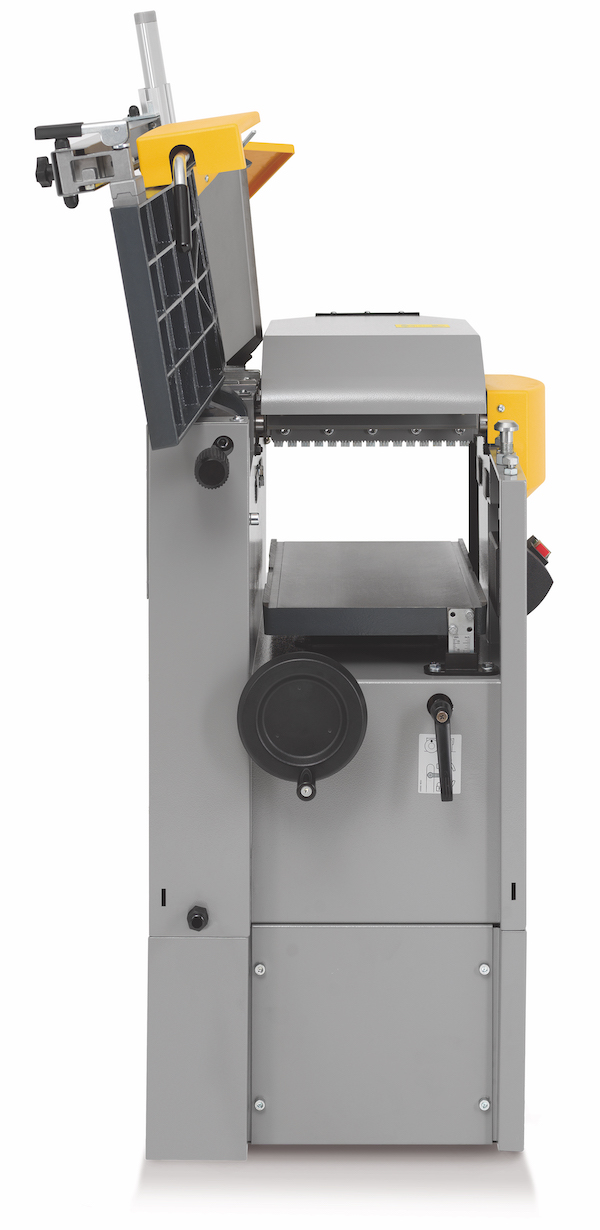

Hammer A2-26 surface planer

Designed to provide quality and precision in small workshops, this new 'small' planer/thicknesser from Felder Group's Hammer range boasts user-friendly operation and impresses with solid cast-iron planer tables

Affordable functionality & reliability

With the Hammer brand for do-it-yourselfers and small businesses, the Felder Group has been producing high quality yet affordable woodworking machines since 1997. Robust, durable, space-saving and precise in their operation, these quality products are designed to make woodworking simply fun.

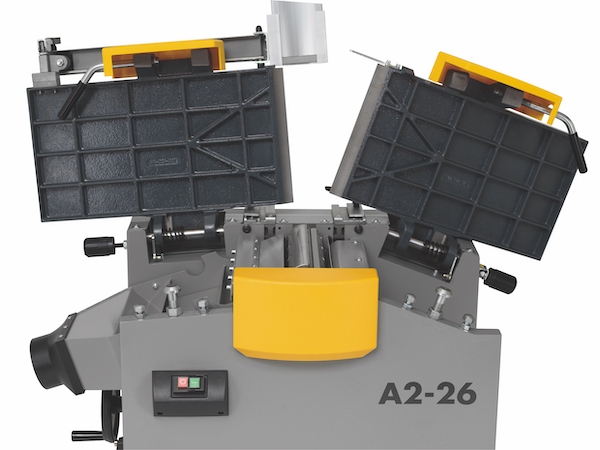

Not only does the new A2-26 impress with its compact dimensions for small workshops, it also meets Hammer planer standards that've been tried and tested for decades. The solid cast-iron planer tables, user-friendly operation, quick and easy changeover from planing to thicknessing and, above all, the reliable Hammer self-setting cutterblock ensure perfectly finished wood surfaces – just some of the remarkable details that shouldn't be missed in the workshop

The most important highlights at a glance

Hammer – decision making reliability for many years to come

Durability, functionality and reliability made in Austria – Hammer woodworking machines are top-quality products from Felder. Since 1997, Hammer has been producing high-quality yet affordable woodworking machines for the skilled trades and crafts. The models have been specifically designed for this customer group and are available in the basic, winner and perform configurations, offering price optimised solutions for every requirement.

Decades of experience building machines, Austrian craftsmanship, strict quality standards and tried and tested Felder system solutions guarantee excellent woodworking machines, the best operating results and customer satisfaction for years to come. From the passionate woodworker to the business owner with high demands, investing in a Hammer machine guarantees reliability and precise woodworking.

REASONS TO BUY A HAMMER MACHINE

* Excellent value for money

* Decision making reliability for many years to come

* State-of-the-art machine technology

* Solid cast-iron tables and units

* High quality, unique detail solutions as part of standard package

* Top quality manufacturing with strict quality guidelines

* User friendly, classic design

* Quality and precision from Austria

* Compact functionality

* Mobile as an option

* Minimal space requirement

* Quickest changeover times

QUICK STATS

* Surface planing width: 260mm

* Surface planer table length: 1,045mm

* Cutterblock: Self aligning knife cutterblock

* Max depth of cut: 3mm

* Thicknessing height: 3-184mm

* Feed speed: 6m/min

Details that convince

Technical specifications for the Hammer A2-26

ELECTRICS

1 x 230V motor voltage; motor power 2.6 HP (1.9kW) – standard

50Hz motor frequency – standard

005 60 Hz motor frequency – optional

PLANING UNIT & CUTTERBLOCK

Three knife quick-change, self-setting cutterblock system – standard

Anodised planer fence tilts from 90-45° – standard

Length of surface planer fence – 700mm

Surface planer width – 260mm

Planing table length – 1,045mm

PLANER & FEED DRIVE

Thicknessing width – 254mm

Thicknessing height min-max – 4-225mm – standard

Thicknessing table length – 497mm

Minimum workpiece length – 145mm

Maximum depth of cut – 3mm

Synchronous feed speed – 4,5 m/min (50 Hz); 5,4 m/min (60 Hz) – standard

GENERAL

Extraction connection Ø – 100mm

Gross weight – with standard configuration – 175kg

IMPORTANT ACCESSORIES

01.1.202 –Indicator clock with digital readout, 0.1mm resolution, counting counterclockwise – 2mm increments – optional

12.1.311 – Aluminium – system – handwheel – optional

210 – Rolling carriage without lifting bar – optional

211 – Lifting bar – optional

Customer service & maintenance

Specially trained service personnel are always available to provide specialised on-site service for you. For urgent enquiries, customers can call the hotline centre for straightforward, immediate help. Consultants can be contacted directly or requests conveniently reported online 24/7.

FURTHER INFORMATION

Typical price: £1,450 (inc VAT)

Contact: Felder UK

Address: 2 Joplin Court, Sovereign Business Park, Presley Way, Crownhill, Milton Keynes MK8 0JP

Tel: 01908 635 000

Web: www.felder-group.com

- Log in or register to post comments