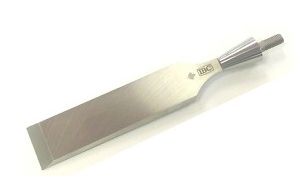

IBC Bench Chisels review

David Charlesworth Evaluates the new IBC Bench Chisels

These long awaited chisels are now available from Johnson Tools www.johnsontools.co.uk who sent me a set for evaluation.

As with many new products to the market, when faced with innovative design, it is difficult to come up with a definitive opinion. Time will tell.

The connection between handle and blade is unusual. The top of the blade passes through a hardened ferrule and then threads into a hardened steel core. This extends to the top, where a solid, polished aluminium cap secures the maple handle. (American walnut is also available as an option).

In the short term I found this arrangement works perfectly well for chopping and paring cuts. The tool feels solid and the rounded aluminium cap is very comfortable. This is marked by a steel hammer so wooden mallet or nylon hammer would be preferable.

Two benefits are suggested by the manufacturer. Replacement handles, may be simply produced in any decorative or exotic wood for those wishing to customize their set. However the length and original diameters (at top and bottom) must be maintained

The second is a more unusual concept. Two complete chisels could be purchased, with four extra blades to complete the set. Blade changing only takes a few seconds. This would save a meaningful sum. This strategy will become even more attractive when subsequent blades become available. (Skew, Butt and Fishtail blades are planned).

IBC bench chisel- blade only IBC replacement handles

Chisels cost £59-95 inc. VAT. Blades with ferrules, start at £37-95 inc. VAT.

The appearance of these chisels is attractive. The timber handles are nicely finished and the grinding of the blades is excellent. I found that slight hollow of length in the back, which is so beneficial, when creating some polish, near to the edge. This work took about 20 minutes, which is reasonable for steel of this toughness. I worked from 800grit to 8,000grit.

IBC tell us that the steel is from AISI High Vanadium A2 tool steel. It is fully stress relieved, triple tempered, cryogenically treated and hardened to 60-62 HRC.

I decided to do a little end grain chopping test, examining the state of the edges under a 40x microscope. Three chisels (L-N, IBC & Veritas PM-V11) were prepared identically, ground at 25 degrees, wire edge produced at 28 degrees, and polished at 30 degrees. I set up a simple jig so that each cut would be 1.2mm thick. I was cutting American cherry which was 15mm thick. Each chisel was tapped 100 times, and the total thickness chopped through was 150mm.

All the chisels showed some wear, but the edges were essentially very similar. This confirmed my expectation of very good blades from IBC.

David Charlesworth 27/10/2015

- Log in or register to post comments