From mighty oaks...

In recent decades, of course, the world has begun exporting more and more products to Britain, and cheaper foreign imports have undermined the tool-making foundations of Sheffield’s giants such as Record, and its subsidiaries Marples and Ridgeway. These were brands that I once considered by-words for quality, and I for one thought it was a sad day when Record gave up its Parkway works and moved its manufacturing overseas.

Clico was another of Record Tools’ subsidiaries. Its forte was making router cutters and other specialist tooling, predominantly for the aircraft industry — a niche which, by the early Eighties, Record no longer considered viable. However, Clico’s overseas sales director, Alan Reid, disagreed. Along with his business partner, David Swallow, he bought the Clico name and its associated machinery, which is how the mighty corporate oak that was Record produced the independent acorn that is Clico.

By the mid-nineteenth century, Sheffield

accounted for 40% of Europe’s steel

production; she had become a mighty

city-workshop that was the heart and soul

of the tool-making industry. Despite this

heritage, there’s nothing of the dark

satanic mill about Clifton planes, which

are objects of beauty and desire

Tool-makers come in all sorts of shapes, of course, and tracing the company’s history reveals that Clico’s initial involvement with woodwork was a rather tenuous one: it supplied specialist cutters to the aircraft industry in an age when timber was a key structural component in aeroplanes, and Britain was a major designer and constructor of aircraft. As the materials used in aircraft manufacturing changed, so Clico changed with them, and the company now supplies tooling specifically designed to work aluminium, fibreglass, and even Kevlar. Today, then, this side of the company is very hi-tech’, with computerised machines working to the ultra-fine tolerances that the aerospace industry demands. Just how demanding that industry is soon becomes apparent when the specific relief angles and pitches required to make the perfect cut in certain materials are explained to you! Get it wrong in the aircraft industry and you tend to make the mistake only once, so it’s little wonder that Clico has developed such an uncompromising belief that quality not quantity should be the prime directive for anything that bears its name.

The company’s decision to apply this philosophy to planes and other woodworking tools came about when a downturn in the British aircraft industry made it desirable for Clico to add other strings to its manufacturing bow. In 1987, then, when the opportunity arose to acquire Morrisons, a Sheffield forging company, Clico bought into a very different set of skills to those used in the aircraft industry, ones that rely on traditional techniques that date back for generations.

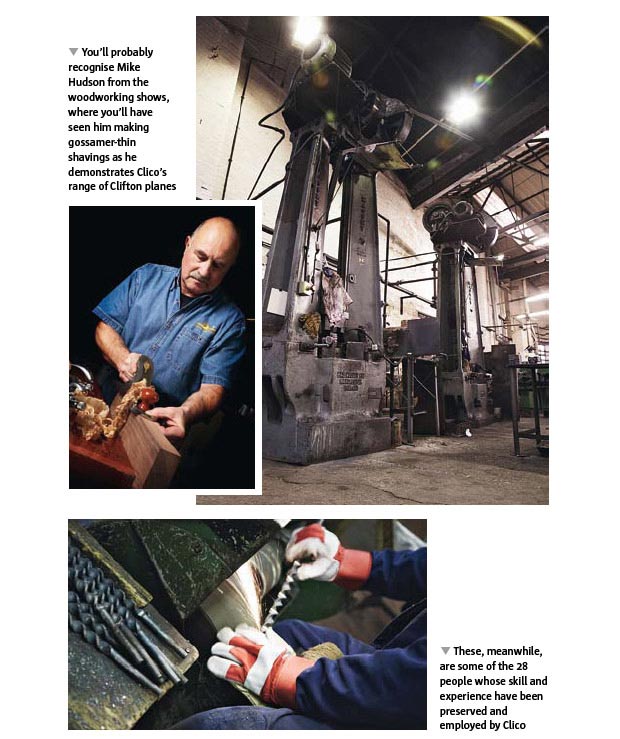

When I arrived at Burton Weir, I was met by Mike Hudson. If you’ve ever visited a woodworking show, you’ll probably have seen Mike, who’s usually to be found wearing his trademark leather apron and making gossamerthin shavings as he demonstrates Clico’s range of Clifton planes. Originally a production engineer at Ridgeway, Mike now has the title of Tooling Development Engineer at Clico. He has a passion for woodworking tools, and an encyclopedic knowledge of tooling. He collects anything associated with Sheffield’s toolmakers — planes, augers, and all sorts of ephemera. I am rather jealous of the fact that he owns a Stanley No1, despite knowing full well that it’s actually too small to be used in a traditional fashion!

The overall running of this site comes under the jurisdiction of Neil Mycroft, the works manager. Neil’s another ex-William Marples/ Ridgeway employee who served his time with them as part of the original Clico set up. He was away on bereavement leave when I visited, but he certainly deserves a mention as the controller of all that I saw! Entering Neil’s domain is like taking a step back in time, with furnaces, hot metal being beaten, and sparks flying! Lovely in the winter, I’d imagine, but not so good in summer!

The back end of the workshop has the forges, with machinery for turning, polishing, and truing the final profiles at the other end. Interspersed along the way are the drop hammers, generating massive deadblows on hot metal to beat and coax it into the desired profiles, with various sets of dies for specific tools as needed.

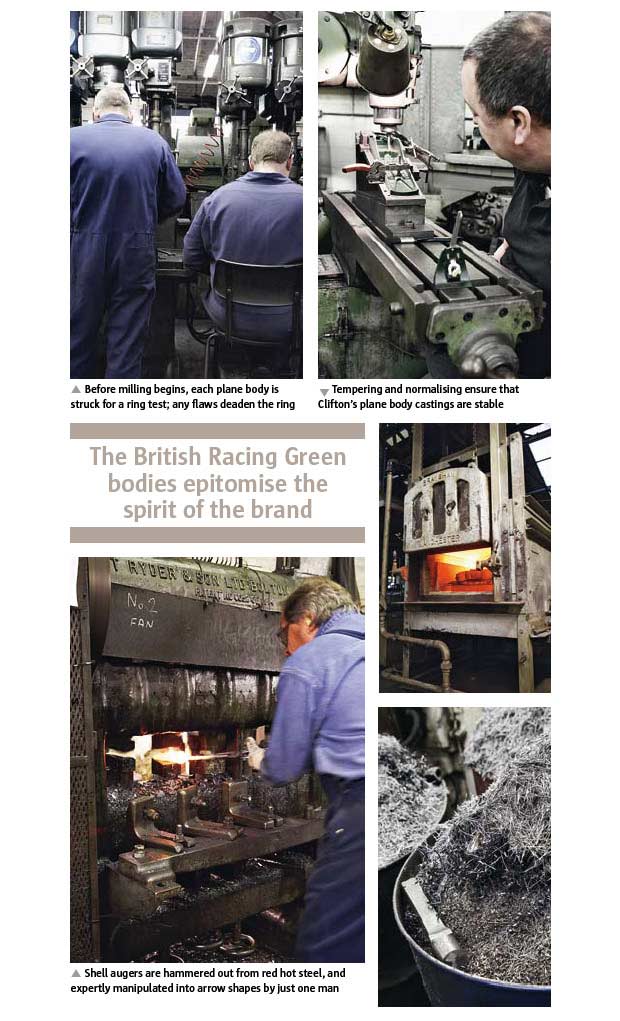

These massive beasts may rely on brute force, but they require a skilled operative to coax the metal into the correct position under the hammer, and know when to move it or remove it. Shell augers were being hammered out from red hot steel while I was there. Starting as round profiles on a shaft, the blanks were expertly manipulated by just one man who worked the glowing metal under a series of small hammers, forging them into arrow shapes ready to be finally made into curved augers, then ground, polished and honed. It’s important to beat and draw the metal in this way, Alan and Mike explained, to give the tool steel the uniform grain structure that gives it superior strength and edge retention.

As supplied, however, the carbon is randomly distributed throughout the raw bar stock, so although the steel is of the right grade, it will neither take a uniform edge nor hold it. Heating and beating the steel changes the molecular structure of the raw material, amalgamating the carbon and steel which become denser and aligned to produce a uniform, high-quality steel — much the same as my mum’s puff pastry, in fact!

Achieving this amalgam depends upon the skill of the workforce, and knowing when to pull the steel out of the forge and beat it, and how long to repeat the process is as much art as science. It’s one of the skills that put Sheffield on the map all those years ago, and the reason why older chisels and plane irons are highly sought after.

Sadly, this hand-forging is an art that’s practised ever less widely. At one time, Alan tells me, factories across Europe employed as many as 3000 people who were capable of turning out hand-forged augers. Today, he maintains, there’re just 28 people with the necessary skill, and one company employing them — Clico. As long as Burton Weir’s working, though, the skill won’t die out. Just take the company’s hand-forged Scotch nosed augers, for example, which are designed for boring into hardwoods.

Plenty of generic wood-boring tools are being mass-produced, but like its aircraft tooling, Clico’s augers are made to suit specific tasks, and can have different lead screw pitches to suit different timbers, and different pitches of spirals to remove the waste. As Mike Hudson freely admits, a cheaper bit will probably do the job in most cases, but what Clico offers is reliability and unwavering performance when it counts. As a woodworker, you may never have to bore holes in a greenheart lock gate before the tide turns, but when you’re putting your heart and soul, time and money into a project, it’s good to know you’re using a tool that won’t bind or fail to draw itself in.

The augers are given a final check for straightness by eye, and any irregularities are tweaked out with an expert tap of a hammer over an anvil. With auger sizes ranging from 1⁄4in up to about 2in, and some as long as 2ft, I’ve nothing but admiration for these guys!

The first planes in the Clifton

range were shoulder planes, as

well as spokeshaves used

specifically for chairmaking

Surface plates and feeler gauges: plane soles are flat to within +/-0.0015in

The first planes in the Clifton range were copies of Preston designs — shoulder planes, and also a couple of spokeshaves specifically for chairmaking. It wasn’t until 2000 that Clifton’s now-famous bench planes were launched at the Atlanta Tool Fair. Since then, of course, the range has been expanded, and seven are currently available: the singles from 3 to 7, with the 4.5 and 5.5 making up the set.

The castings for the planes are poured by another company that uses Clico moulds and specifications, which call for additional thickness on the wings and also around the mouth area. They then come into Burton Weir’s plane department for machining, and here is where I have to admit I don’t know as much about grey iron as I thought!

I’ve long sung the praises of ductile bodies for planes on the grounds that they won’t fracture or break if dropped; grey iron, on the other hand, has a harder structure and can break. Alan, however, pointed out that grey iron comes in different grades, from manhole cover material to high-end iron such as Clico uses. This has a tougher, more durable molecular structure, and while it cannot be guaranteed that a plane won’t break, I was shown videos of planes being dropped from up to 20 feet and surviving! More importantly, they suffered no distortion either, and this gives grey iron the upper hand over ductile iron, whose more pliable nature can allow it to bend or twist. This distortion my be minimal, but it can be enough to prevent the tool from working correctly.

I also saw a plane body that looked as if it had been deliberately struck with a hammer: it had a very deep ding on its edge, but again there was no casting breakage, so I’ve changed my tune on ductile iron versus grey iron!

And speaking of tune, before milling begins, each plane body is struck for a ring test. As with a bell, any flaws in the castings, such as an occlusion, will deaden the ring, providing a quick and easy way to weed out imperfect castings. Even so, machining can throw up other pits or flaws where the casting has a pocket of air, and these too are consigned to the scrap bin for recycling.

It’s during this cooling stage that the additional thickness of the castings comes into play. For maximum stability and to minimise brittleness, the casting needs to cool at the same rate. Being thinner, however, the mouth and wings tend to cool more quickly. Adding extra material to these areas, then, slows their cooling, encouraging the whole casting to normalise at a uniform rate. Once the process is complete, the extra material is simply machined away.

Interestingly, this ‘settling’ can be achieved by simply leaving the castings to their own devices. When I visited the Record foundry about a year before it closed, for example, I saw huge piles of plane bodies outside, seemingly rusting away. They were, in fact, settling. Clico’s approach, however, is a much more controlled one, and takes just days rather than months.

Geoff checks each plane on a surface plate to ensure that the final polishing surface grind is doing its job perfectly; any tools that fail to meet the required standard are returned for an additional micro-fine skim.

The frogs are fitted to equally exacting tolerances, their seats being ground perfectly flat so that they can move as needed, but without any racking or twisting.

It’s this close work that ensures the parts seat perfectly to give the solid, chatter-free set-up that enables the planes to work so well. What really sets the planes apart, though, is Clico’s final attention to detail. I was surprised, for example, that the lever cap is actually a polished casting; I always assumed that it was a chromed finish such as the Stanleys and Records of old. A range of polishing mops, each loaded with different grades of cutting compound are used to attain the high gloss, and I was told that a specific final compound is used that imparts a ‘blue’ lustre to the finished metal. And indeed it does!

‘Buy once, and buy well’ is a good rule of thumb, and thanks to Clico, and a few other like-minded companies, the discerning woodworker can still buy British, and buy with the knowledge that the tools are made to the highest of standards.

- Log in or register to post comments