Weapon of choice

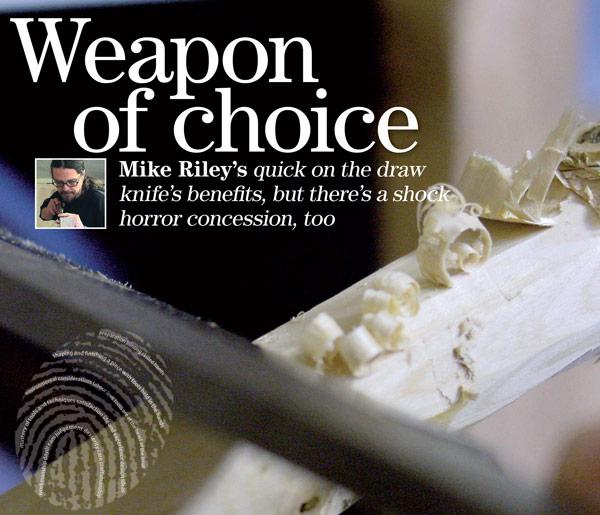

Unguided edge tool: from wasting to delicate shaping, the draw knife can be made a jack of many trades

There must have been a time when every woodworker had a draw knife in his toolbox. It’s the only way to account for the vast number available today in secondhand tool shops and on eBay; my friend even found one buried in a field recently, and after being cleaned up, he was able to press it back into service. If you don’t want to go metal detecting, though, and don’t want to buy a secondhand draw knife, Classic Hand Tools or Ray Iles will sell you a new one, or you could even make your own — old and worn-out files are perfect blade donors.

But there I go again, getting ahead of myself. What is a draw knife, you’re wondering, and what’s it for? If you’ve never come across this tool, it’s really nothing more than a large blade with two handles, though there are variations in the design to suit different applications. While it’s a simple tool, the draw knife has a large range of uses, from stripping the bark off rough timber, to putting decorative chamfers on the finest furniture. These days, it’s most commonly used for rounding turning blanks, though many turners now use a bandsaw for this purpose. You’re also likely to see the draw knife in the hands of a traditional green woodworker, or a stick chair maker. The latter will use it for making the legs, rungs and back posts, and then possibly take up another form of draw knife – the scorp – with which to saddle the seat.

The shave horse is a good

aid when using the draw knife

It was the lack of a bandsaw in my workshop, as well as a chat with Bruce Manning in The Real Dave Roberts’ back garden, that started me thinking about using a draw knife. Not having a bandsaw limits my ability to cut straight lines, and anything requiring curves has meant breaking out my fretsaw, which I’ve never managed to master and which seems more inclined to create a pile of snapped blades than curved profiles. A draw knife, on the other hand, can take the heaviest of cuts, wasting away wood quickly to get down to a scribed, curved line.

It was for this reason, then, that I thought I might be able to get by with a draw knife instead of a bandsaw for some tasks. However, after a good deal of practice, I discovered that a draw knife can also take the lightest cuts to chamfer edges or to create delicate curves and rounded sections. From being a replacement for a bandsaw, the draw knife has become my tool of choice for many shaping tasks, even to the exclusion of the spokeshave.

Now, brace yourself for a rare admission. I can’t help thinking that although the draw knife can waste wood away from a blank as fast as a bandsaw, if not faster, the result is a pile of waste material, rather than off-cuts, which may have had a use other than in the fireplace. In an age of limited and expensive materials, this highly wasteful and probably inappropriate use of resources could be avoided by using a bandsaw. There, I’ve said it! I’ve justified powered machinery in the hobbyist’s workshop.

The thing that causes me the biggest problem when using a draw knife is also its biggest strength. Although essentially an unguided edge tool like a chisel, I think it’s closer to the plane family of tools, as the blade is drawn along the work to slice it, rather than directed at paring specific areas as you would with a chisel. But of course, it lacks a sole, which means that while it’s capable of extremely fine work — the shorter the sole of the plane the more focused its application can be — you have to be careful that the blade doesn’t dive into the wood and rip out large chunks along the grain. This is very easy to do, ruining hours of work with a moment’s inattention: the workmanship of risk again. For this reason I tend to start with bigger stock than I would otherwise use so as to allow myself a chance to rectify mistakes. Of course, this is a fl awed kind of logic, as I still have to get to my target dimensions, and the risk of ruination along the way exists until the moment I stop cutting. And if anything, starting with stock that is too oversized is just as wasteful.

With any tool work, good work-holding is essential, but in this case it isn’t just a matter of keeping the work from moving. Usually, I clamp my work either in my bench end vice or in an old Record vice on the bench top, depending on how big it is. When using a draw knife, however, you need the work to be easily movable so that you can reposition the piece frequently and accurately. You also need to be able to reapply secure clamping after each movement. If you can’t, not only does this make working with the draw knife unnecessarily fiddly and time-consuming, but I think it tends to encourage you to work too long in the same spot and so lose track of the overall target shape. I’m always aware that I spend too long or focus too closely on smoothing out the facets that the tool creates rather than roughing out a shape first and then returning to the finish work at the end, which is how it should be done. This often leads to an imbalance in shaping that it’s not always possible to rectify without starting all over again.

The tool can be used to remove timber quickly or make the lightest cuts

The shave horse is designed specifically for this problem. It consists of a three-legged bench on which the user sits with a clamping arrangement; this is locked and released by foot power, holding the work stationary for shaving but also allowing for quick release and repositioning. One of the main benefits of the shave horse is its portability, as it can be set up wherever you need it. This might mean, as it once did, that it’s carried into woodland to the material, or simply into the back garden in summer months. My experience thus far with the draw knife tells me that a shave horse is essential, and I will be building one.

The alternative is something known as a shaving pony, which is essentially the same quick release clamping device, but held in the bench vice. One downside is that the operator must work standing on one foot, as the other foot is used to operate the clamp. This is not only tiring, but also potentially dangerous to both woodworker and work, and it means that you’re anchored to the bench rather than positioned comfortably.

Left: In appearance, the draw knife is essentially a chisel with two handles, it’s perhaps better likened to a plane without a sole

Right: The draw knife is now Mike’s shaping tool of choice. It’s what enabled him to create his elegant wooden spoons

Breast bibs?

Another means of holding work when using the draw knife is one which I have also used with smaller pieces: the breast bib. This is just a squarish scrap of wood – I used 10mm plywood for mine, with two small holes drilled in adjacent corners, through which a length of twine is threaded. The breast bib hangs around the neck and sits on the chest like a baby’s bib, not only keeping your lunch off your workshop apron or shirt, but also giving you a thick solid surface to pinch the workpiece against without impaling yourself on the end of the wood. It can also act as a kind of woodworking Kevlar in the eventuality that you get carried away with the draw knife; but you’d have to be extremely clumsy to draw the blade into your body, as it requires that your shoulders, elbows and wrists are all behind your point of contact. I personally find that quite an effort to do on purpose, let alone by accident, although it’s possible that my difficulty is just a sign of incipient old age.

To buy a draw knife of your own visit www.classichandtools.com, or www.oldtools.free-online.co.uk

I can see that it’s possible to achieve great things and fine work with a draw knife, although it’s definitely a tool which requires, and rewards, practice; it won’t give instantly useful results. This is perhaps one reason why they were once so prevalent in the toolbox, but less so now. Once I’ve fully got to grips with the tool, however, there is a long list of projects where I can see it being useful. Most of these call for a shaping tool, which is where I think the draw knife can excel, at least in hands more skilled than my own.

While I still think that a draw knife can be used instead of a bandsaw for rough ripping and shaping of stock, I do think this is a wasteful and avoidable process. Therefore, I have to admit that there is a plausible case for machinery here. In fact, I can see that a bandsaw might have a useful and economical application for the workshop of the small-scale professional or hobbyist.

- Log in or register to post comments