Benchmark of Quality - Part 2

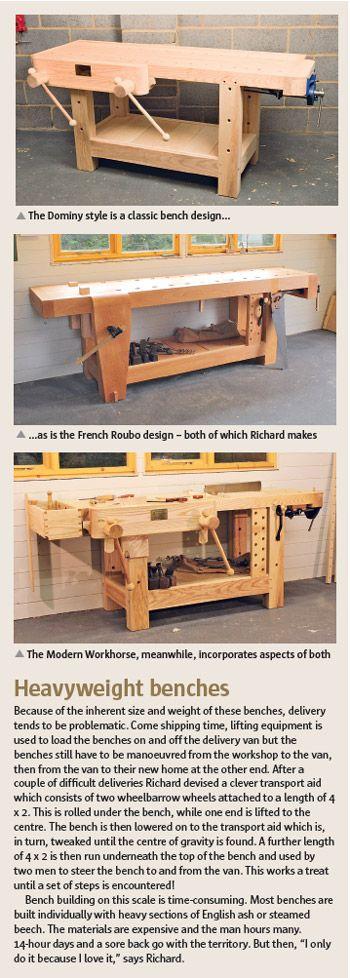

This past couple of years has seen Richard take to the workshop as a full time occupation, building furniture to order for all sorts of clients – some even prepared to pay well. More recently though, the bulk of workshop time has been dedicated to a new venture: making some of the finest woodworking benches around. Richard has chosen to concentrate on two classic designs, the Dominy with its splayed rear legs and the classic French Roubo bench which features a traditional front leg vice, complete with wooden screw, and a modern version of the classic wagon vice imported from America.

There’s a third model too, termed the Modern Workhorse. This boasts a lovely looking design, incorporating the solid undercarriage of the Roubo bench with the versatility of the Dominy’s top.

Believe it not, there’s over £2,000 worth of cost involved with making a Roubo Journeyman, the 8ft 6in (2.6m) version of this classic bench, which is one of the largest standard benches Richard makes. Wood is expensive and with a 5in-thick solid ash top you’ll appreciate that building this Roubo requires a lot of timber, not to mention six men to lift it! The hardware is expensive too, adding significantly to the cost. On the other hand the 6ft Modern Workhorse will set you back considerably less, if you’re in the market for a fine workbench. After that you’re into the realms of a custom build where each bench is priced individually. Richard’s next job is a 10ft Roubo custom featuring twin leg vices at the front and a wooden twin screw vice at the end.

Buying a top-end bench like this isn’t really about price, it’s more about value. The service, the design, attention to detail and sheer quality of these benches is – in my opinion at least – certainly worth more than the asking price.

Plans are afoot, however, to create a more economical range of benches. Talking me through the designs, Richard says they will be based on a Roubo base but with custom designed knock-down fittings so the benches can be disassembled for easier delivery. The tops will be 4in (102mm) thick and supplied in two full-length 9in (229mm) wide slabs. A removable tool tray will make up the middle section, between the two slabs. You will then have the option of using the tool tray or flipping it over so that the bottom becomes part of the bench top surface.

The really clever bit, though, is the thinking behind the 9in slabs. As we all know, solid wood moves, and to get the best from a bench the top will need a bit of adjustment with a fore or jointer plane once or twice a year to account for movement between the seasons. Many purchasers of Richard’s benches are apprehensive about taking a hand plane to their new bench top, but with this new economy range they won’t have to because the 9in slabs are designed to go through the average-sized thicknesser.

The hands-on approach

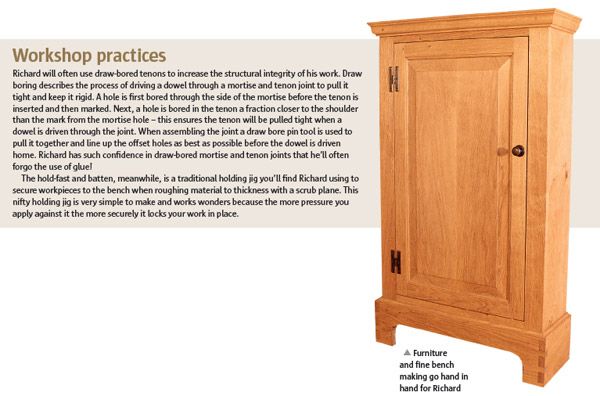

Despite the present focus on making quality benches, Richard still takes enormous pleasure in his furniture. Just take a look at his beautiful black marble-topped oak sideboard, completed for a client only the day before. The piece was made almost entirely by hand with just a little help from a bandsaw during the first stages of the project, which is a pretty incredible feat. All the components were planed by hand; the undersides of the drawer bottoms and base panels had been finished the traditional way, with a scrub plane, leaving those lovely long scallops that bear witness to the scrub plane’s use. Of course, the client has to be willing to pay the price for a piece built almost exclusively by hand, so Richard was lucky with this commission. “I love the furniture, that’s where the heart is,” he says. “If I stopped making furniture then I’d stop making good benches.”

The scarcely believable thing here, though, is that Richard manages to make such stunning furniture – all by hand – and yet can justify it financially. Just how does he manage to match the speed of power tools? “If you’re going to learn how to work by hand properly you have to learn how to cut corners,” he reveals. This may sound strange, especially if you’re used to the common view of purist woodworking, but stop and think about it for a moment and it makes perfect sense.

A good example of proper corner cutting is leaving scrub plane marks on drawer bottoms and the unseen sides of panels. Another is to mark just one side of a mortise before cutting it by hand – the width of the mortise chisel will take care of the other side as you cut. Dovetails can be cut without time-consuming marking too, simply cut by eye straight after scribing the depth of cut, chop out the waste with a coping saw, then, and only then, take the time to mark the pins with a knife before cutting. The results look beautiful as you can see in the photo on p54.

All this takes a lot of practice to perfect but it’s amazing what the body can do. Richard will plane a piece of timber and know it’s square – he does it that often that there’s no need to check the results. “You do almost become like a machine yourself,” says Richard. “It’s weird how something organic can become ‘engineered’.”

Inspired at the bench

Some people like to make their own bench, while others prefer to concentrate on the part they enjoy – actually making furniture – and let others, who specialise in bench making, provide them with an ultimate solution. I remember reading James Krenov’s book, The Fine Art of Cabinetmaking, when I first started out in the early ’90s; his advice on benches has been hard-wired ever since: “Get (or make) a really good workbench. It will be about seven feet long (2.20 meters) and cost a mint, but do get it nonetheless.”

Seeing Richard Maguire’s benches reminds me that I’m still making do and, one day, I’ll give this area of the workshop the attention it deserves. In the meantime one thing is for certain – Richard is busy making those 7ft benches that cost a mint, and if Krenov saw them he’d surely approve. If you can’t afford one of young Maguire’s benches, though, at least you can take some courage from his exceptional bravery, determination and hard work. He’s a man that demonstrates what it means to strive against adversity and come out the other side better for it.

INFORMATION

For prices and more photos on his benches:

Tel: 07767702915

- Log in or register to post comments