sauter router lifts & Suhner router motor

As a woodworker, can you get by without a router? If you’re a Luddite, you’ll probably have to, but these days, it’s probably more a case of how many routers someone owns as opposed to whether or not they have one at all.

Hand-held routers are great for shaping, chamfering, cutting joints, mortising, inlaying as well as a plethora of other workshop tasks, but in order for a router to be used safely and effectively on smaller jobs, you’ll also need a router table.

Router table challenges

In my experience, this is where life can get a little traumatic – starting with the fact that the plunge routers we tend to use in the UK aren’t really designed for use in a table. When a router is strapped upside down to a simple insert in this configuration, it still needs to utilise its plunging function in order to control the depth – height – of cut. There’s several obstacles to overcome here, notably when adjusting cut height and when changing cutters. There’s exceptions to the rule, but the process of adjusting cut height will usually involve grovelling around on your knees, pushing the router upwards against the force of its springs, and fighting to make fine adjustments with the depth stop.

Changing cutters usually also presents a challenge – sometimes you can access the collet from above the table, but you’ll often need to fumble about underneath with a couple of spanners, and there’s a certain inevitability that at some point in the proceedings, you’ll end up with blood pouring from your knuckles. So, what’s the answer? Well, clever people have come up with some ingenious devices that can be added to a plunge router to make cutter height adjustable from above the table, and collet extenders can make changing cutters a much less bloody affair. I’ve tried some of them and they do work, up to a point, but don’t offer a complete solution.

The other, potentially much more robust, accurate and user-friendly solution, is to invest in a router lift, and there’s plenty to choose from. The big difference here is that the lift does all cutter height adjustments independently of the router’s plunge function, and some models make use of a motor that’s been removed from a fixed base router – the sort of thing that’s generally found in North America. If using one of these motors in the UK, however, you’ll need some clever electronic kit to convert 240V into the 110V required. A few years ago, in a bid to solve this challenge, I tried – albeit with a little trepidation – a dedicated Chinese 240V motor of the correct diameter in a fancy North American router lift. Now, perhaps I was just unlucky, but having gone through about half a dozen of the same motors in as many weeks, I admitted defeat and ended up asking for a refund.

At this point, I must confess that I’d also given up on my main router table, which was now fitted with a fancy lift and no motor. I resolved to, one day, fit my fancy lift with a motor marked ‘Porter Cable’, rather than ‘PRC’, and try to sort out the voltage problem, but in the meantime, I’ve been managing with my very portable router table setup, fitted, when needed, with my 1/2in plunge router. I’ve always been optimistic, however, that one day, someone might come up with the perfect UK router table system... so, could I have found it?

sauter router lifts

Why, then, had I not heard of sauter router lifts before? Perhaps I need to get out more, but when I was asked to test one of their lifts, which happened to be of the highest quality, designed and made in Germany, my interest was piqued. I asked about motors suitable for use with this lift and was told, by sauter, that they could also supply a dedicated, high quality, German-made motor to fit it. At this point, I was feeling hugely optimistic that I may, finally, end up with a router table solution that wouldn’t annoy me every time I got anywhere near it, not to mention a motor that would last for more than five minutes. The final bombshell was the announcement that the other lift model not only went up and down with consummate ease, but also had a pivoting/tilting function. This all sounded mighty impressive, and I was eager to test this German wizardry for myself.

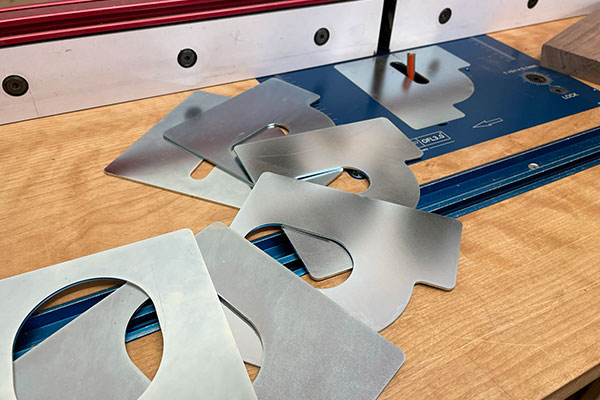

sauter’s router lifts are designed and made by their own engineering team and available in three main options – OFL 1.0, OFL 2.0 and OFL 3.0. Here, I tested the OFL 2.0, which has a magnetic reducing plate system to control the size of opening around the cutter; the pivoting OFL 3.0, which features the same reducing plate system and also pivots/tilts; and lastly, a dedicated, German-made Suhner router motor.

sauter OFL 2.0

Out of the box, my first impression of the OFL 2.0 was that it’s a robust, well-engineered and nicely finished piece of kit. There’s lots of shiny, precisely machined steel and aluminium, and the top insert plate is machined from a stylish blue anodised aluminium. It features really good clear, white graduations and markings, which are laser-etched into the top surface. According to sauter’s technical department, this particular lift is designed to fit at least 28 different plunge routers from various manufacturers – possibly more – or, with just two bolts, it can be fitted with a 43mm adaptor and used with a dedicated motor, such as the Suhner.

Fitting the lift requires the correct sized opening and rebate in the table top, which is easily achieved using a jigsaw and router if making your own table, but the 307 x 230 x 10mm dimensions are pretty standard for any commercially produced European router table. As I soon discovered, however, and not overly surprisingly for a country that’s still stubbornly clinging to the imperial system, in my table for the North American lift it was replacing, the hole and rebate were of different sizes – a little longer and not quite as wide; however, if you have a router, then adjusting the width doesn’t really pose a problem.

Optional extras

sauter supply an optional 1mm-thick steel levelling frame, which sits neatly in the bottom of the table recess, and something I’d recommend as it gives the levelling grub screws – located in each corner of the lift – something solid to sit on, rather than ply or MDF, which is slightly soft and unlikely to aid precision.

In use

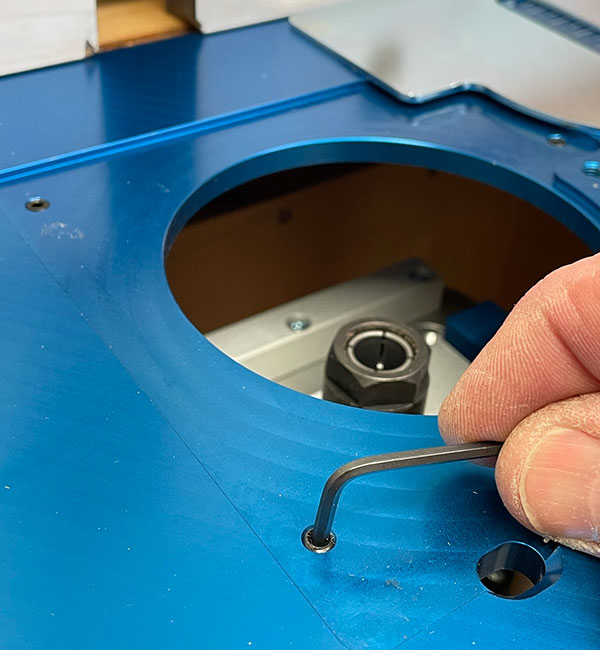

To fit a standard plunge router to the lift, consult the supplied chart for your make and model, which tells you which of the many supplied screws, bolts and washers you’ll need as well as the corresponding holes to put them in. Using my Festool OF1400, according to the chart, I’d require two M6 countersunk screws inserted in the holes marked ‘F’ in the installation plate, a hex key to tighten the screws and the router securely fixed. To complete installation, you simply plunge and lock the router at its full depth – so far, everything seemed very straightforward.

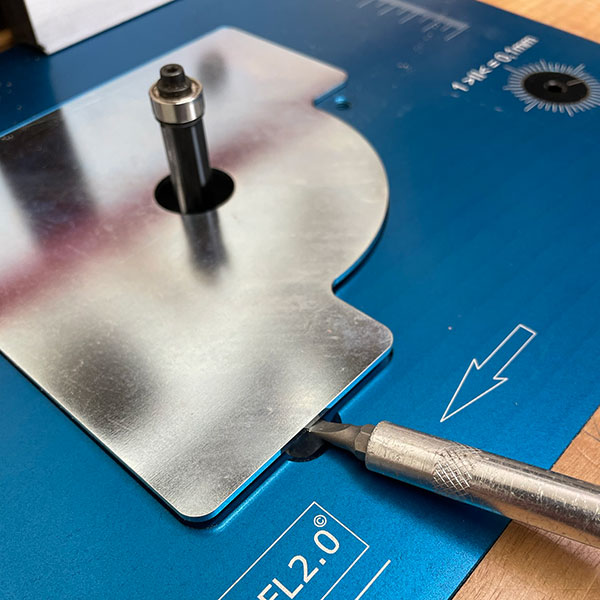

With router fixed into the lift, the entire construction can be dropped through the table hole so that it sits on the levelling frame in the rebate. Four fixing screws, nuts and washers secure the lift into the table and two grub screws in each corner are required to level the insert plate with the table top. The OFL 2.0 has three magnets imbedded in the insert plate, meaning that when the reducing plates – metal plates with different diameter holes to achieve minimum clearance around whichever diameter cutter is being used – are dropped into the recess, they snap securely in place. Once again, it’s important to level these plates with the insert plate’s top surface, which is quickly and easily achieved by dropping one or two of the supplied 0.1mm circular metal shims into the recess, above each of the three magnets. Although the reducing plates are securely held, they’re still very easy to remove by inserting a flat-bladed screwdriver into the little scoop located in the recess’ front edge.

Cutter changing

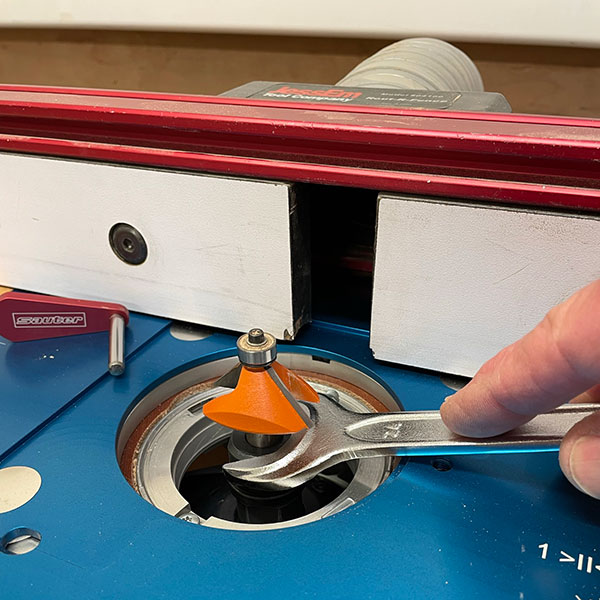

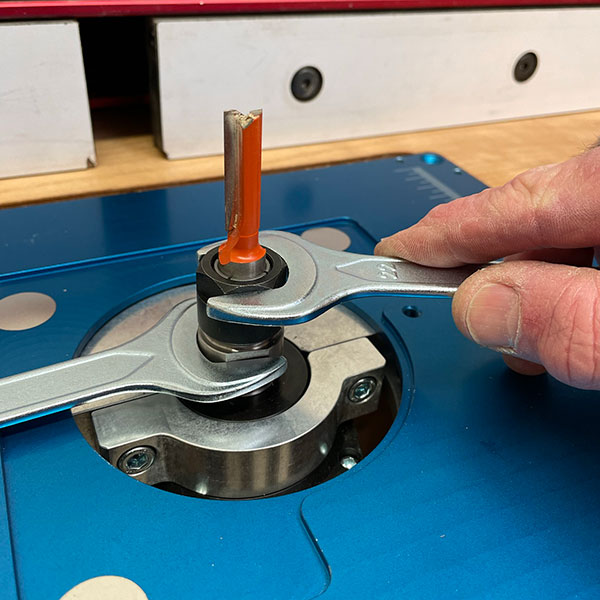

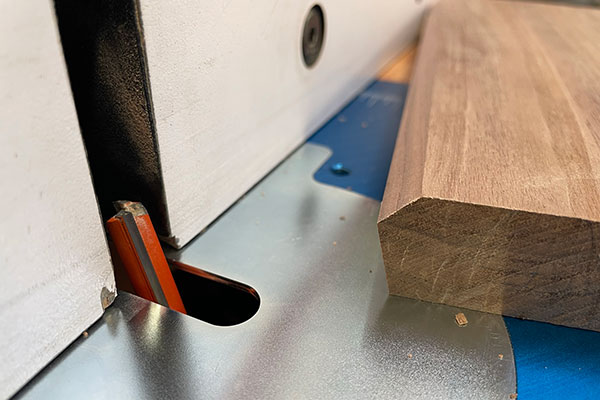

In terms of fitting a cutter, this can often be a challenge on router tables, but the OFL 2.0 seems to have everything under control and well thought out – well, what did you expect? You start by removing the reducing plate to reveal a nice large opening, then use the little hex winder handle to fully raise the lift. At this point, with the router already plunged to full depth, the collet is easily accessed from above the table. On mine, I needed to depress the spindle lock from beneath the table, but I’d luckily remembered to ensure it was facing forwards, which made it easily accessible, and with a single spanner above the table – which had to be held at a very slight angle – cutter changing proved to be a thoroughly pleasant and painless process.

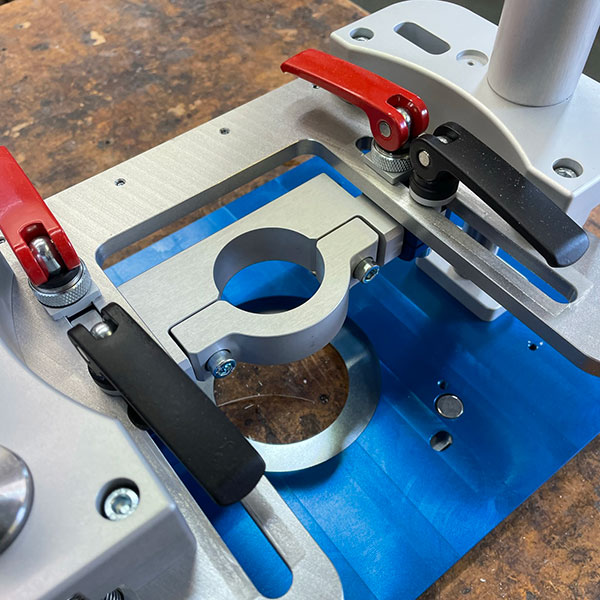

The black lock levers control tilt and the red levers allow the installation plate and motor to slide backwards and forwards

Having installed a cutter and fitted an appropriately sized reducing plate, it was then time for some routing. If you’re using a fence, for straight work, there’s some really useful 1mm graduations marked on both sides of the insert plate, which are great for keeping track of the fence position when making fine adjustments and, if necessary, keeping it parallel. These markings run almost to the back edge of the insert plate, which means that if your fence has parallel front and back edges, you can reference from either of these as appropriate. For freehand work, perhaps when using templates for curved work, there’s a threaded hole in the insert plate, just to the right of the reducing plate recess, along with a pin and guard, which can be securely screwed into the hole to provide good control at the start of a cut.

Making adjustments

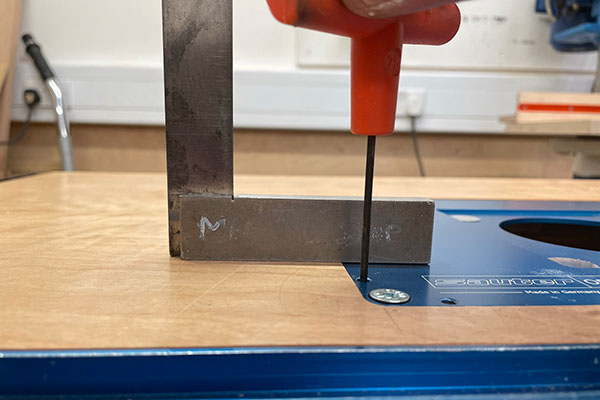

Cutter height is adjusted using a neat 5mm hex hand crank, which is inserted into the appropriate hex hole: one hole adjusts, the other locks. One complete turn of the handle equates to exactly 4mm, and there’s a fine white line on the adjuster and around it with equally fine markings at 0.1mm intervals, all of which makes precise adjustments an absolute breeze. The first thing you notice when raising or lowering the lift is that it’s super smooth and there’s absolutely no slack in the mechanism, which is incredibly important when trying to make very, very fine height adjustments. I’ve come across several router lift systems where the cutter height drops slightly as soon as you release the lock, and/or requires a partial turn of the adjuster before there’s any movement in the cutter height, all of which makes achieving these incredibly frustrating. I experienced none of that with the OFL 2.0, however, just precise, smooth and accurate results.

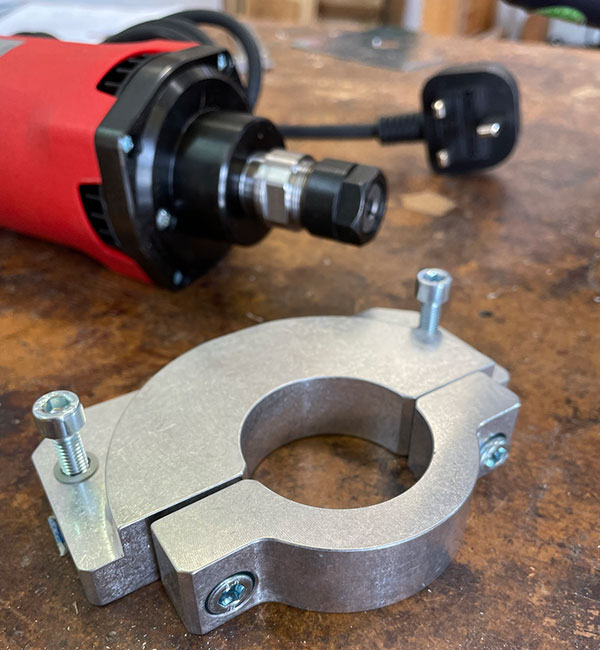

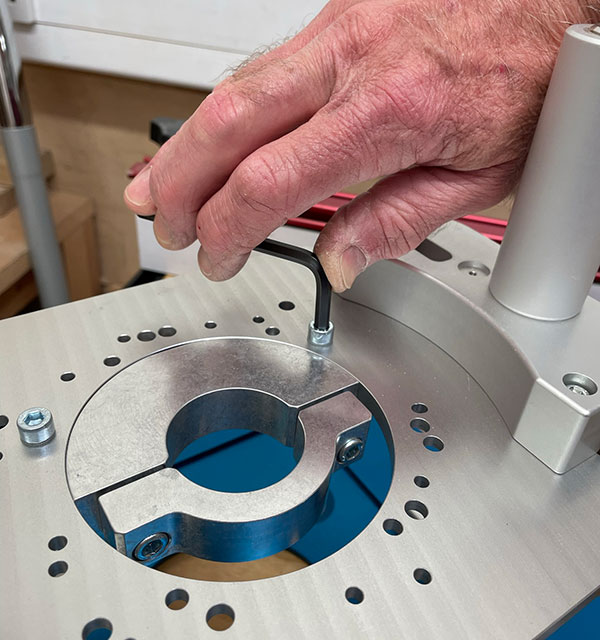

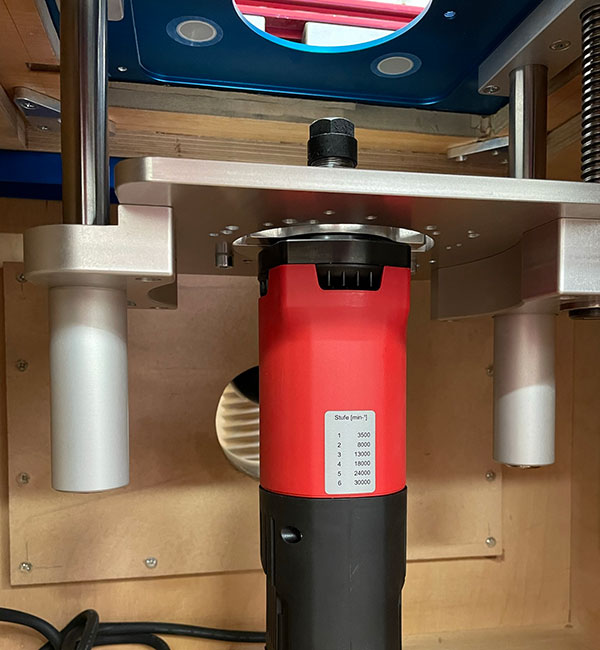

For freehand duties, despite the fact that removing a router from the OFL 2.0 is a fairly quick and easy process, you do have the option of installing a dedicated motor. Doing so involves adding the optional 43mm diameter adaptor plate onto the installation plate, which requires just two screws, in place of a plunge router. Several motors are available with a 43mm neck, all of which run on 240V. The Suhner motor supplied for this test is described as ‘industrial quality’ and also ‘made in Germany’. With 43mm adaptor fitted, the motor is simply clamped in, again using two screws. With dedicated motor fitted, access to the collet for cutter changing is even easier than before – when fully raised, the entire collet assembly is nicely positioned above the table’s top surface, which makes this process completely hassle-free.

sauter pivoting router lift OFL3.0 I had a slight suspicion that there was something of the dark arts at play when it came to the sauter pivoting router lift OFL3.0. Of course, being able to tilt the cutter on a spindle moulder, while by no means a standard feature, is nothing new and can be incredibly useful, but a router lift with tilting/pivoting capacity isn’t something I’ve ever seen before. An off-the-shelf router lift with this ability could certainly be something of a game-changer – if it works!

The OFL 3.0’s insert plate has exactly the same dimensions as the other sauter lifts, but this time the installation plate can only be fitted with a motor with a 43mm neck, such as the Suhner. Apart from the tilt function, the only other subtle differences are the fact the insert plates have different sized slots rather than holes, although plates with holes can be used, and these are levelled using three grub screws rather than shims. Otherwise, the features are identical, including the laser-etched markings, micro height adjuster and lock.

Pivoting/tilt function

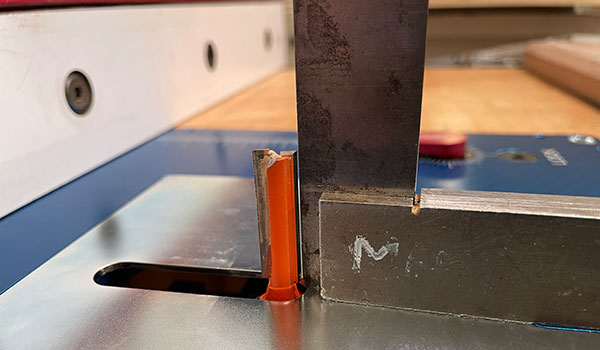

So, what about this revolutionary feature? Looking under the table, two black levers are positioned at the front and two red levers just behind the motor, all of which are fairly easy to access. The other thing to notice, with reducing plate removed, is the Vernier scale to the right of the collet, which is used to set the cutter to one of five preset angles, or any other angle required, in one degree increments from -5° to +50°. The presets are the ones you’d probably expect – 0, 15, 22.5, 30 and 45° – and to initiate a ‘tilt’, all you have to do is release the two black levers and pull the motor towards you for anything up to 50°, or push away for up to 5° of negative tilt.

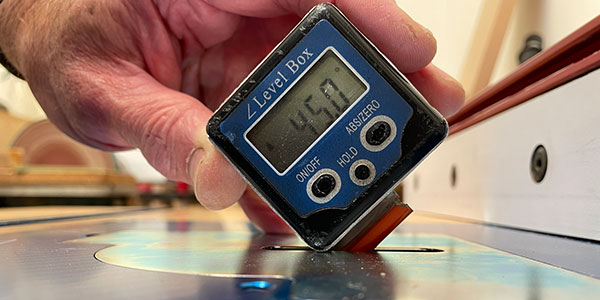

As you move the motor, the presets are easy to feel although there’s definitely a little play at each ‘click’. If you do require precision with the angle setting, a digital level box or similar will provide the necessary help. Setting back to zero has the same slight problem, with play at the preset, so to ensure accuracy, you’ll need a square. These accurate angle adjustments don’t really present too much of a challenge, however, and you can always add a little pressure from the black lock levers when making adjustments; this prevents the motor moving too easily and gives plenty of control to proceedings before fully locking into position.

In use

A consequence of this tilt function is that as you head towards higher angles, there’s a danger that cutters will get very close to, and ultimately hit the back edge of the reducing plate, or even the insert plate. This is where the red levers come into play, and when these are released, the installation plate and motor can slide forwards. So, if both the black and red levers are released, the cutter is able to tilt backwards as well as slide forwards – just slide the motor forward enough so that the cutter can’t hit anything, then lock the red levers in place. When returning back to zero, with the red levers loosened again, just slide the motor back to the ‘stop’ position and it’ll be nicely centred in the reducing plate. You might be thinking that a micro-adjust mechanism would be nice for the tilt function, but I actually really love the simplicity of this system, which, with just a little practice, works remarkably well.

A fancy pivot/tilt facility on a router table is all well and good, but does it actually serve a purpose? Well, you can obviously achieve ny chamfer angle your heart desires, not just those available using a standard chamfer/bevel router cutter. You can angle grooves for the bottom of a box, with angled front or sides, and accurately add angles to edges/ends, perhaps when constructing projects with compound angles. All of a sudden, this sort of tricky angled cutting on smaller components becomes quick, easy and safe, perhaps encouraging you to add more adventurous shapes to your woodworking projects. You can also, of course, create many more shapes for mouldings and moulded edges by angling standard, shaped cutters.

Suhner UAK 30 RF SPZ12 UK motor

As mentioned earlier, with the OFL1.0 and OFL2.0 router lifts, you have the option of using a dedicated router motor by adding the 43mm adaptor plate, while for the pivoting router lift OFL3.0, a 43mm motor is the only option. Various makes and models of motor can also be used, which feature this neck size, but here I tested the Suhner UAK 30 RF SPZ12 UK – a powerful 1,530W motor with soft-start and variable speed from 3,500-30,000rpm. It accepts collets up to 1/2in (12.7mm) and the ‘UK’ on the end signifies the fact it’s fitted with a 3-pin UK plug. Unlike a plunge router, this motor is designed to cope with being hung upside down in a router table and the on/off switch has a robust looking dust cover. After all, dust can be really unhelpful if it happens to find its way into a switch.

Six positions are marked on the speed controller dial, although it’s infinitely variable, and situated on the side of the motor body is a really helpful, clear chart, which lets you know the spindle speed that each number equates to; something you’d normally have to search for in a manual. Today, router cutters are generally marked with the speed they should be run at and with this motor, there’s no guesswork involved when it comes to achieving optimum running speed for all your cutters. This is an industrial quality motor, which features all the precision you’d expect from a German-made item. The soft-start function ensures quiet and incredibly smooth operation, and all in all, it just looks, feels and sounds like a quality piece of kit. Changing the carbon brushes, which will inevitably wear out one day, is a very simple operation and should anything ever go wrong with the motor, spare parts and support are readily available – not something that’s usually straightforward with machines hailing from the Far East.

Conclusion

Overall, both sauter router lift models and Suhner motor appear to be thoughtfully designed and incredibly well made. With this in mind, the price point reflects these high quality touches and build quality, and as we all know, you get what you pay for. Now that I’ve discovered this piece of kit, I’m actually looking forward to using my router table, and the precision, ease of use and reliability available is just what I’ve been hoping to find for a very long time.

Taking all these points into consideration, I have a good feeling this router lift and motor combination will provide many years of trouble-free service, not to mention lots of happy routing adventures ahead!

Specification

Router lift OFL 2.0K – features exact height fine adjustment and magnetic reduction plates Distance from top edge of inlay plate to baseplate of mounted router: 15mm

Dimension insert plate: 306 × 229 × 9mm

Insert plate corner radius: 6mm

Height adjustment travel/rotation: 4mm

Max. adjustment travel: 108mm

Height milling lift – max. extended: 240mm

Max. cutter diameter: 86mm

Approximate weight: 4.5kg

Pivoting router lift OFL3.0 – from -5°to +50°

Dimension insert plate: 306 × 229 × 9mm

Insert plate corner radius: 6mm

Height adjustment per rotation: 4mm

Max. adjustment travel: 74mm

Router lift height – max. extended: 240mm

Max. router bit diameter: 55mm

Approximate weight: 5kg

Suhner UAK 30 RF SPZ12 UK – industrial quality 1,530W router motor

Accepts collets up to 12.7mm (1⁄2in)

Clamping neck: Ø43mm

Input power: 1,530W

Infinitely variable speed: 3,500-30,000rpm

Torque: 0.45Nm

Voltage: 230V

Noise level: 72dB at 9,000rpm

Including collet chuck: 1/4in

Weight: 2.85kg

Further collets can be purchased separately

Typical prices: sauter router lift OFL2.0 – €439; sauter pivoting router lift OFL3.0 – €649; Suhner UAK 30 RF SPZ12 UK router motor – €489; 43mm motor adaptor – €65.01; 1mm steel levelling frame – €16.76; 5mm hand crank – €15.88

Note prices include 19% VAT, but exclude shipping costs. Depending on delivery address, VAT may vary at checkout. Various lift, accessory and motor packages are also available Web: www.sautershop.com

THE VERDICT

Pros:

* Well designed and excellent German-made build quality; lifts are easy to fit and level in a table; plunge routers or dedicated motors are equally straightforward to fit; very easy, precise cutter height adjustment; good access for changing collets/cutters; magnetic reducing plate system is quick and easy to use and features a good range of sizes; pleasing range of imperial and metric collet sizes; spares and repairs readily available; guaranteed to make you smile!

Cons:

* With the OFL 3.0, the small amount of play in the preset angle stops won’t ensure accurate angle settings; accuracy requires a little operator intervention in addition to a gauge; the 43mm Suhner motor is Industrial quality and consequently not cheap, but quality always tends to come at a price and other, more competitively priced options are available if preferred

RATING:

PERFORMANCE: 5 OUT OF 5

VALUE: 4.5 OUT OF 5

John Lloyd runs a range of woodworking courses in Sussex – for more information, see www.johnlloydfinefurniture.co.uk

- Log in or register to post comments