‘Chevron’ chest of drawers

Created by Andrew Lawton – one of our three expert judges for the Alan Peters Furniture Award 2022 – this chest of drawers is made from solid blackbean – a rich, beautiful hardwood, similar in appearance to walnut, but denser, harder and heavier.

A native Australian timber, blackbean exportation ended in the 1970s, but Andrew was lucky to acquire four 2,400 × 170 × 75mm planks from a long-retired maker, who was selling off his remaining stock. As such, this particular piece, British-made and contemporary in appearance, is very rare and unique.

The design

Intended to provide plenty of useful storage space with a small footprint, this particular design had existed in sketchbook-form for several years. The ‘Chevron’ theme is evident in many of Andrew’s pieces, the first being a ripple sycamore desk made in 1993. Since then, he’s gone on to create numerous others and the chest of drawers shown here features chevron-shaped sides.

Andrew explains further: “I’d originally considered using English walnut, but having acquired the blackbean planks, I soon realised that in addition to colour and grain, their dimensions were also ideal for this project.”

Stages of making

The first stage taken by Andrew was to prepare a full-size drawing of the piece, showing front and side elevations, plus a plan, which was drawn in pencil onto an MDF sheet. Any adjustments to dimensions and detailing were then carried out. “Looking at a full-size drawing from the normal viewing position can often suggest changes and improvements, which aren’t always obvious on a paper drawing or computer screen,” he comments.

Next, each plank was examined and the one with the most interesting grain chosen for the drawer fronts and carcass top; the less highly figured boards were used for the sides. The full width drawer rails, made using ash and featuring 50mm wide blackbean lippings, are, in effect, shelves on which the drawers slide. Since the grain runs in one direction, any movement is therefore in the same plane.

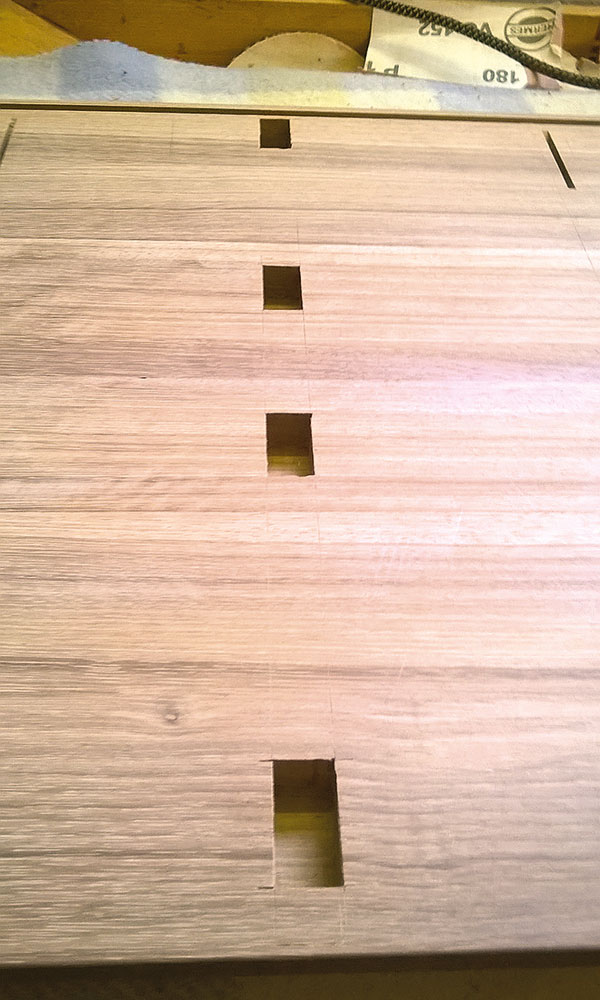

For the two carcass sides, each was built up from six individual staves, tapered in length and shaped to a 30° bevel. This proved to be a fairly exacting operation, requiring a jig, which was achieved using a bandsaw, planer/thicknesser and tilt-arbor saw bench, followed by careful hand planing with a Record No.7 try plane. The butt joints were shot by hand and biscuit jointed for accurate alignment, and for the main carcass joints, Andrew chose housed stopped – blind – mortise & tenons.

“Considering the blackbean’s density and in places, rippled and interlocked grain, it was relatively easy to work using both hand tools and machines,” says Andrew. “It is, however, slightly oily, so as a precaution, all joints were degreased with cellulose thinners prior to assembly.”

Once carcass glue-up was complete, it was then a matter of allowing the adhesive – Titebond Original – to set. Andrew could then carefully check internal faces with an engineer’s straightedge to ensure that each surface was dead flat and the carcass wasn’t narrower at the back than the front. “Accuracy of the carcass interior is vital if the drawers are to run smoothly and truly, so time spent here always pays off.”

For the drawer sides and back, quartersawn sycamore was chosen; it provides an attractive colour contrast to the blackbean, followed by cedar of Lebanon for the bottoms. As with all drawers produced by Andrew, the dovetails are hand-cut. Oak drawer pulls were ebonised using a home-made solution of vinegar containing old steel screws, which was left to soak for a few days prior to application.

Finding the right finish

Deciding on a suitable finish can sometimes be a challenge, but in this case and in view of the blackbean’s oily nature, Andrew selected Danish oil, which brings out the sheer richness and variety of shades while providing adequate surface protection. The drawer sides and backs were finished with clear wax and the bottoms left bare, so as to not impede the cedar’s scent.

Measuring 1,350mm high × 550mm wide × 410mm diameter, the completed piece features a carcass back in sycamore veneer on an MDF core, which is slotted into a groove before being secured in place with brass screws.

Andrew Lawton

Andrew creates furniture that’s fit for purpose, using high quality materials throughout and the best constructional methods for the job, with the joints themselves forming a decorative design element where appropriate. Much of his work has a geometric rather than organic feel, which is partly a result of Andrew’s fascination with Art Deco and Modernist architecture.

The majority of Andrew’s work is made to commission, although he also makes several speculative pieces every year, which are offered for sale at exhibitions and directly from his small showroom. Enquires are invited for any single item or room scheme that requires distinctive and individual handling, for private homes, corporate clients and public buildings.

To find out more, see the website: www.andrewlawton.co.uk.

- Log in or register to post comments